|

Building a

1/32 scale XA-32

|

The model was scratch built in pretty much my usual

way, but there were some problems that required a bit of thought, among

them the fact that the cockpit interfered with the wing assembly, mounting

the large stabilizer high on the fin, and dealing with the fairly complex

cowling.

The in-progress pictures pretty well tell the story,

but here are a few notes to accompany them.

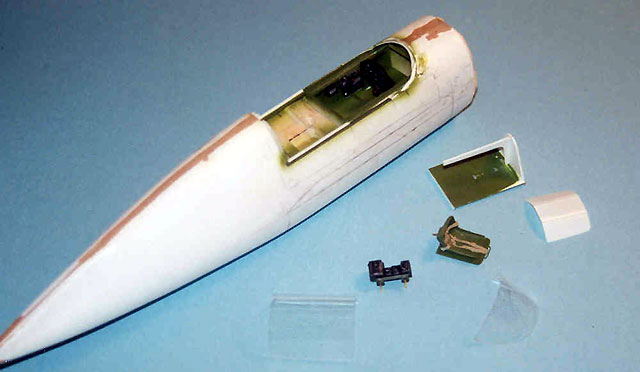

Basic construction was the usual vacuum-form-over-balsa-molds for the

wings, fuselage and tail surfaces.

The plastic fuselage forms were glued onto the molds after the appropriate

wood was removed for the cockpit. The cockpit itself was built as a tub

inserted into the fuselage. The interior was mostly scratch-built using a

number of Waldron pieces and the Cutting Edge 1/32 scale posable seatbelts

from Meteor Productions (which I think are great, by the way). The canopy

was molded from 1/32nd plexiglass, and the gunsight was scratch-built.

Click the

thumbnails below to view larger images:

The cowling probably took as much time as several of the other pieces

combined. It was first vacuum-formed without the upper and lower scoops.

After the front opening was cleaned up, two more pieces of plastic were

heated-and-smashed on the top and bottom of the cowling and these were

glued into place thus making the scoops.

I chose this way because, from the side, the cowling

curves up more on the bottom than it curves down on the top; therefore, I

needed the formed plastic to keep the proper compound curves.

The spinner was turned from basswood and the prop

blades were cut-down 24th scale Bandai P-51 left over from a Mustang I

conversion. The most tedious part of the cowling was at the rear. The cowl

flaps were cut out and then replaced in the open position. After that, 18

holes were drilled around the cowling (they were staggered and not equally

spaced), and 18 small deflectors (pretty much like those on the B-25) were

formed over a mold, cut, sanded and then glued in place over each hole.

Tedious, but satisfying when finished.

The vacuum-formed tail surface skins were epoxied onto the balsa cores.

The stabilizer was then cut in half and re-glued to the proper dihedral

using brass pins for strength.

The vertical tail was cut in two and the chord-shape of the stabilizer

removed. The lower half was then glued to the fuselage and the stab and

upper section of the rudder added on top of that. All attachments were

made using long brass tubing or wire to give the required strength.

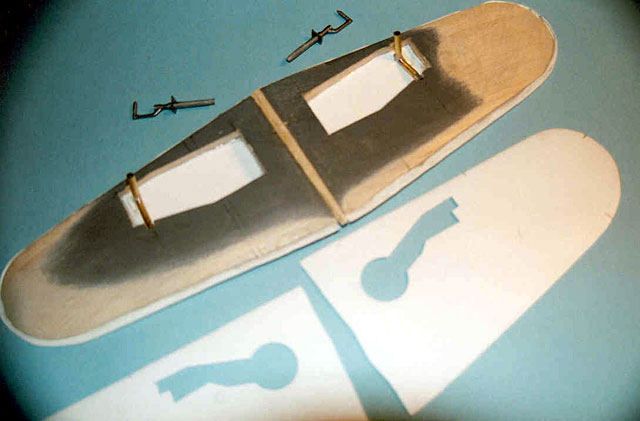

The wings were made by first cutting the wood mold in half and removing a

section from the upper center section that would have otherwise interfered

with the cockpit tub. The wings were then re-glued with the proper

dihedral, and braced with some brass tubing.

The wheel well openings were cut from the wood, and the upper plastic

surface attached with epoxy. Detailing of the wheel wells was then done

followed by construction of the landing gear. The wheels, tires, and parts

of the gear leg were also taken from the remains of the Bandai 24th scale

P-51. The rest of the gear was scratch-built. After this detailing was

done, the bottom surfaces of the wings were epoxied in place and the wing

was cleaned up.

The gear doors needed a bunch of pieces, but were fairly straightforward.

It was nice to have only one gear door per side (the retracted wheel was

not covered). The tail wheel is non-retractable. Landing and nav-lights

were also added.

This particular bird is the XA-32A, the armament test aircraft. I chose it

because I thought the cannon looked cool. The cannon housings were made by

heat-and-smashing 8 halves over a turned mold and gluing them together

after trimming. The barrels were aluminum tubing which had to be plugged

and filled since, at least at the time the pictures were taken, they were

dummies.

Click the

thumbnails below to view larger images:

All the control surfaces were cut out

and re-installed, and for once, I did not open the flaps/dive brakes (it

had them on both the upper and lower surfaces).

After priming and sanding, all the parts were

scribed. I know that I will always lose some of the scribing during the

assembly process, but it always seems easier to me to repair rather than

try to do it all after the main pieces are assembled.

The wings and tail were attached to the fuselage and all the fairings were

added/cleaned.

Sanding, puttying, sanding, etc., was then done and

the scribing touched up where necessary.

The finish on the airplane was silver lacquer, which

is kind of boring, but it did avoid a lot of natural-metal work.

Decals were scrounged from the scrap box. When it was finished, I just had

to picture the thing alongside a Revell P-47 dating from many years ago.

It was big.

Bottom line: One more weird airplane to add to the shelves. At least

Trumpeter won’t be bringing it out a month after it was finished.

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright © 2003

by Frank Mitchell

Page Created 31 July, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search