|

Yak-1b

by

Tony Bell

|

|

|

Yakovlev Yak-1b |

Accurate

Miniatures' 1/48 scale Yak-1b is available online from Squadron.com

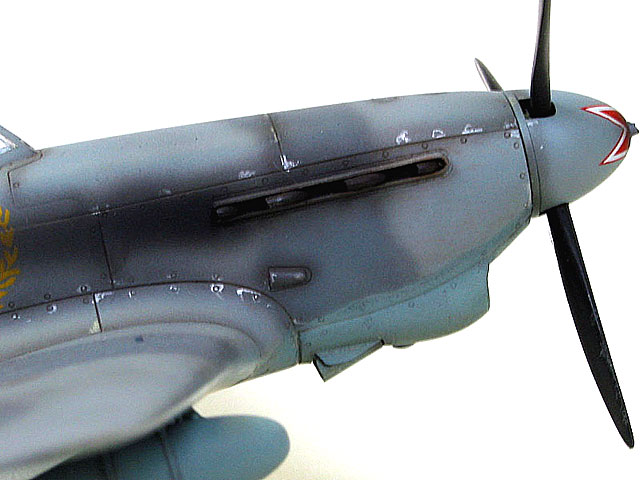

The progenitor of a long

series of Soviet fighters culminating in the Yak-9, the Yak-1 was produced

from 1940 through to 1944. A fairly conservative design for it’s day, it

featured a tubular frame fuselage with aluminium skins over the nose with

a plywood and fabric rear fuselage, much like the Hawker Hurricane. The

wings and empennage were plywood with fabric control surfaces. The -1b

version differed externally from the Yak-1 in that it had a cut down rear

fuselage and carried a single 13mm machine gun.

Accurate

Miniatures' Yak-1

|

Upon opening the box, one is

treated to the usual Accurate miniatures packaging. All the sprues are

bagged separately and there is a false bottom under which are the clear

parts and decals. The surface detail consists of finely recessed panel

lines and fasteners, with restrained rivet detail in places, most notably

on the lower wings. The kit is entirely devoid of flash, sink marks or any

other moulding flaws.

Having built both the

Accurate Miniatures F3F-2 and B-25C, I was already well aware of the

wisdom of reading, studying and following the kit instructions carefully.

As usual, the construction started with…

The Cockpit

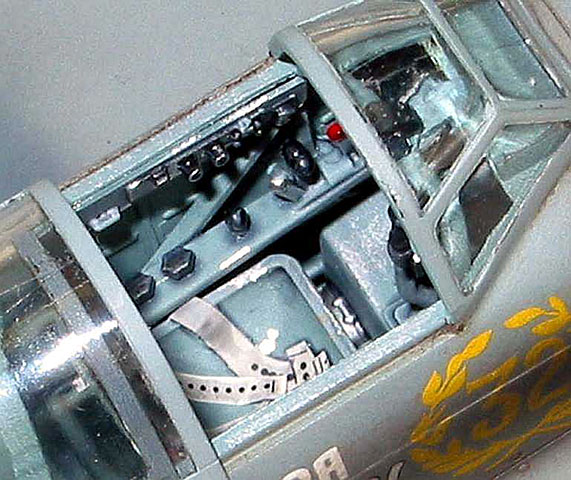

As this was to be a

"straight from the box" build, I added nothing to the kit cockpit, which

was assembled per the instructions.

The

cockpit was painted overall Testor Russian Underside Blue, with details

picked out in black and silver with a few red bits for some colour. I

applied a “wash” of Poly Scale flat mixed with black ink and thinned with

water and then drybrushed the whole thing with light grey oils. The seat

harness decal was applied to masking tape for a more three dimensional

look. It too received the Poly Scale wash to give it more depth. The

instrument panel is typical of Accurate Miniatures, being moulded in clear

styrene with a reverse printed decal to be applied to the back side of the

panel. The

cockpit was painted overall Testor Russian Underside Blue, with details

picked out in black and silver with a few red bits for some colour. I

applied a “wash” of Poly Scale flat mixed with black ink and thinned with

water and then drybrushed the whole thing with light grey oils. The seat

harness decal was applied to masking tape for a more three dimensional

look. It too received the Poly Scale wash to give it more depth. The

instrument panel is typical of Accurate Miniatures, being moulded in clear

styrene with a reverse printed decal to be applied to the back side of the

panel.

Easily the highlight of the

kit, the Yak cockpit went together easily with no problems whatsoever, in

contrast to my experience with the F3F-2 cockpit. It’s no surprise that

the aftermarket resin companies have ignored the Accurate Miniatures Yak

cockpits, as the detail is superb right out of the box.

Click the

thumbnails below to view larger images:

The Fuselage

This is where I started to

encounter some problems. The fuselage consists of three main components:

the left and right halves and the upper deck. I had read about the tricky

fit of the upper deck and so was prepared to do some dry fitting and

fiddling to get it right.

First I glued one fuselage

half to the upper portion, let it dry completely and then attached the

other half. This resulted in a nice, tidy join along the length of the

fuselage, but left a seam on the deck behind the cockpit which would be

visible through the rear canopy. This seam was filled with Mr. Surfacer

500 and sanded smooth with bits of sandpaper glued to pieces of wood cut

to fit in the opening. After this was accomplished, the cockpit area was

painted Underside Blue and the armoured glass behind the pilot attached

with white glue. The forward and rear portions of the canopy fit well and

were attached with liquid cement. A bit of Mr Surfacer 1000 was all that

was required for a perfect join. The canopy was masked off with Tamiya

tape. Because the frames were well defined, it was possible to trim the

tape in situ with a new No. 11 blade, having taken care not to consume any

caffeine in the previous six hours!

Another problem was the oil

cooler outlet door under the nose. This absolutely refused to sit

properly, and in the end I had to cut the hinge pins off, thin the forward

edge of the fuselage opening and aft edge of the door and carefully glue

it in place while holding it with a pair of tweezers to prevent it from

falling inside. The radiator outlet door was somewhat easier and only

required thinning on the trailing edge. The seam on the underside of the

fuselage was filled with Mr. Surfacer. The fabric detail was masked off

with electrical tape to avoid damage when sanding the seam smooth. Lost

rivet detail under the nose and radiator was replaced with a pounce wheel.

The horizontal stabilisers

fit well, only requiring a bit of Mr. Surfacer to fill the seam. The Mr.

Surfacer was brushed on and allowed to dry for about 20 minutes, and the

excess wiped away with a cotton swab moistened with methyl hydrate,

avoiding the need for any sanding.

The Wings

I had also read that the

wing root join was potentially troublesome, so I elected to attach the

upper wing halves to the fuselage first. This is where not following the

instructions got me into trouble as I had neglected to install the cockpit

before hand. A substantial amount of bending and prying was necessary to

get the cockpit into place, but fortunately nothing broke or split in the

process.

The wing spar was clamped in

place in the lower wing to force the two together and generous amounts of

liquid cement were used to ensure a strong bond. The carburettor intake

was a separate piece and required considerable shimming, trimming and dry

fitting before it could be attached to the lower wing without the need for

filler. It should be noted that the intake is completely inaccurate, being

too small, round and flush, as well as missing the splitter plate. The

intake in the Eduard Yak-3 is much more accurate.

The lower wing was attached

to the rest of the model, with the spar locking the cockpit into place.

The left wing was fine, but the right wing had a pronounced warp to it.

This was straightened out by steaming and twisting the wing back into

shape.

The separate ailerons fit

nicely and were attached with liquid cement. The wing tip lights fit

poorly but, due to the lack of surface detail in the area, were easy to

fill and blend in. I applied instrument decals to the back sides of the

wing tank fuel gauge covers, which were then glued into place and sanded

and polished to blend them in with the wing surface. Circles of Tamiya

masking tape were punched out with the Reheat punch & die set to mask the

gauges off.

Painting,

Weathering and Decals

|

As is my usual habit, I

started off by spraying Tamiya black along the panel lines to “pre-shade”

them. The undersides were painted Testor's enamel “Russian Underside Blue”

(how could I go wrong?) Instead of thinning the paint with mineral spirits

or lacquer thinner as usual, I decided to experiment and thinned it with

“automotive paint reducer”. This is actually a lacquer thinner, but is

considerably less volatile (i.e. “hot”) than the regular stuff. The paint

flowed beautifully, adhered well and dried hard with a slight sheen.

Once the undersides had

hardened for a few days, I masked the demarcation line between the upper

and lower colours with a roll of Blu Tac. The upper camouflage colours

were sprayed with Aeromaster enamels Russian light and dark grey (9070 and

9071, respectively), again thinned with automotive paint reducer. If

anything, the Aeromaster paints worked even better than the Testors.

A coat of Future floor

polish was sprayed on as a precursor to applying the decals. Oddly enough

the Future beaded up horribly on the Aeromaster colours, but went down

fine over the Testors. I overcame this by applying a heavy, almost runny

coat of Future over the upper surface. I had never encountered this

problem before and attributed it to the paint reducer. Some

experimentation revealed that wetting the surface with alcohol immediately

before spraying the Future allowed it to cover properly.

The kit decals were thin,

well printed and reacted well to both Gunze Mr. Mark Softener and Microsol.

I managed to wreck the starboard patriotic slogan decal when I handled the

model too soon after applying it. Fortunately I had a spare set of decals

and was able to replace it after carefully removing the remains of the

first attempt. The rest of the decals went on without incident, including

the potentially tricky spinner decal.

Weathering consisted of a

Windsor and Newton burnt umber oil wash in the panel lines and paint

chipping done with Humbrol silver No. 11 and a 0000 brush. Because the

wings were wood and the rear fuselage was fabric, I made sure I applied

chipping only to those areas that were actually metal on the real

aircraft.

The whole model was sprayed with Aeromaster acrylic flat, and the exhaust

stains airbrushed on with a brown/black colour mixed from Tamiya paints

and thinned 90% with rubbing alcohol.

Accurate Miniatures

thoughtfully provide separate wheel hubs and tires, which simplifies

painting. They also provide the option of round or slightly flattened

tires. I opted for the flattened tires and painted them Aeromaster acrylic

tire black and the hubs were painted underside blue and glued to the

tires. The tail wheel was painted in a similar manner and glued in place.

The landing gear legs were

painted the same colour as the undersides, with Testor Raw Umber for the

leather oleo covers.

Attaching the landing gear

gave me considerable difficulty. While the lateral location of legs is

fool proof and impossible to misalign, the fore-aft rake allows for

approximately 20 degrees of play. I had to break off and reattach the left

leg twice to try to align it with the right, and still I didn’t quite get

it right. My advice is as follows: glue the lower (inner) gear door to the

gear leg temporarily with white glue and glue the upper (outer) door

permanently to the gear well edge. Next glue the gear leg and retraction

strut to each other and to the wing spar, lining up the trailing edges of

the doors. Let everything set up completely and repeat for the other side

and take the time to line both sides up. Check the alignment from the

sides, top, bottom, front and back.

Once everything has dried

completely, pop off the lower (inner) gear doors and attach the wheels,

taking care to get the flat spots to sit properly. Finally, reattach the

lower gear doors.

I have determined that a great deal of my modelling enjoyment is derived

from my expectations of the kit in question.

For instance, when I set out

to build the ICM MiG-3, I was expecting to have to put a lot of effort

into test fitting, detailing, refining, etc. As it turns out I was

correct, but still enjoyed the kit immensely. In contrast, I was expecting

a shake & bake OOB when it came to the Yak. After all, it was Accurate

Miniatures, wasn’t it?

Because of this unrealistic

expectation and in spite of the fact that it was a much easier build than

the MiG, I didn’t enjoy this kit nearly as much.

Click the

thumbnails below to view larger images:

Model, Images and Text Copyright ©

2003 by Tony Bell

Page Created 24 June, 2003

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search