|

Classic Airframes' 1/48

scale

Canberra T.17

by Brett Green

|

|

|

English Electric Canberra T.17 |

Classic

Airframes' 1/48 scale Canberra T.17 is available online from Squadron

For a

detailed examination

of the contents of Classic Airframes' 1/48 scale Canberra T.17, see the

in-box review elsewhere on HyperScale.

The English Electric Canberra was a groundbreaking

aircraft when it entered service in the early 1950s. The Canberra set

and held many altitude, distance and speed records in its early years.

In addition to widespread and long service with the Royal Air Force, the

English Electric Canberra was exported to many countries including

Australia, New Zealand, Sweden, France, West Germany, India, Pakistan,

Rhodesia, Ethiopia, Argentina, Chile, Ecuador, Peru and Venezuela.

The Canberra's service record was remarkable in its longevity, spanning

from the Suez crisis to Vietnam to the Persian Gulf. In fact, the final

Canberra PR.9s in RAF service are only due to retire this year.

The Canberra T.17 was a specialized Electronic Counter

Measures/Electronic Warfare variant converted from the B.2 bomber. 22 of

these aircraft were produced specifically for a joint RAF/RN unit, 360

Sqn. The bomb bay and the newly designed nose housed the additional ECM/ECW

equipment. The Canberra T.17 had retired from service by the mid-1990s.

Classic Airframes' 1/48 scale Canberra T.17 kit shares much in common

with the earlier B.2 and TT.18 releases, but includes a new forward

fuselage with the unique nose and an additional 20 resin parts. The

complete kit comprises 42 parts in grey styrene; 41 parts in grey

colored resin; 11 clear injection molded parts; instructions; plus a

decal sheet and painting guide for two aircraft.

Not surprisingly, construction was very similar to

Classic Airframes' Canberra B.2 (finished

as a GAF Canberra Mk.20) that I built earlier this year. This time,

however, I did manage to avoid a few problems by applying the lessons

that I learnt the first time around.

Parts Preparation

I started by cutting off all the plastic parts and

cleaning up the sprue connector points. This did not take long as there are only 42 parts, although some of these are very large!

Next, I took to the resin casting

blocks with my Dremel motor tool fitted with a grinder bit. I ran an extension

cord outside, brought along a container of water to keep the resin parts

wet (to reduce dust), donned a respirator mask and started work.

Properly prepared and with this power tool, the casting blocks were off

in no time at all. Even with the resin parts damped down, however, there

is a lot of flying resin dust so, if you plan to use a motor tool for

this job, I strongly recommend that you do so outside and wearing some

form of face mask.

Cockpit and Fuselage

Before starting the cockpit, I glued the port-side

fuselage half to the port-side nose; and the starboard-side fuselage

half to the starboard side nose. The result was two complete fuselage

halves, perfectly aligned where the nose meets the main fuselage part

with no gaps or steps whatsoever.

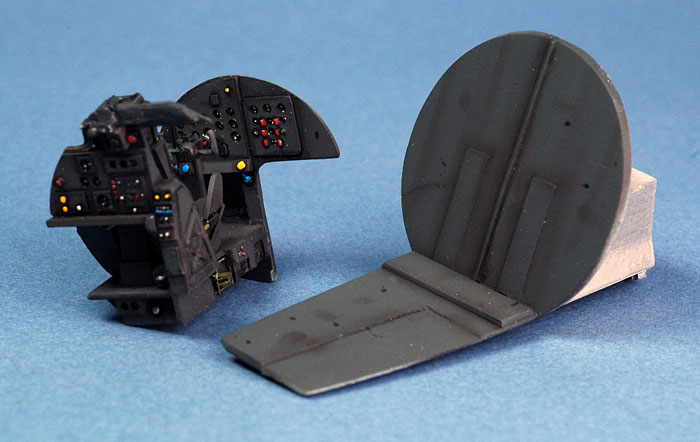

Next was the cockpit. This is made up of a well-detailed

jumble of resin and plastic parts, including two ejector seats.

The interior parts received a coat of Tamiya German Grey

(acting as "scale black"),

followed by streaking and staining. This was achieved with a thin mix of

Tamiya Flat Black and Red Brown applied with the Testor Aztek airbrush

fitted with the fine (tan coloured) tip. Structural details and natural

shadow areas were then further deepened with a selectively applied black

oil wash. The interior parts received a coat of Tamiya German Grey

(acting as "scale black"),

followed by streaking and staining. This was achieved with a thin mix of

Tamiya Flat Black and Red Brown applied with the Testor Aztek airbrush

fitted with the fine (tan coloured) tip. Structural details and natural

shadow areas were then further deepened with a selectively applied black

oil wash.

Details on the instrument panels and side consoles were picked out in white, yellow and red paint. Instrument

lenses were filled in with semi-gloss black and dial detail added using

white paint applied with a sharpened toothpick. I

decided not to install the navigator's Martin-Baker ejection seat just

in case I needed to add extra nose weight later.

I then glued the cockpit floor to the front bottom lip

of the rear bulkhead. This wheel well / bulkhead / floor assembly was

glued to the port sidewall. Now, the pilot's position was slid, without

glue, into the opening under the instrument panel. I test fitted the

instrument panel bulkhead on the sidewall and, when I was happy with the

position, I simply ran liquid glue along the join on the sidewall.

Test fitting showed that the cockpit floor was a bit too wide to permit

the forward fuselage halves to meet, so the side of the floor was

thinned and trimmed until a gap-free result was possible. This is not

difficult, just an exercise in trimming, sanding, test-fitting and

repeating until the fuselage halves met along the centreline.

Click the

thumbnails below to view larger images:

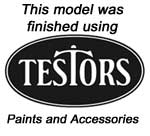

One of the blessings of that bulbous nose is the

additional space available for nose weight. I thought I had plenty of

weight in the front of my first Canberra, but in the end it was not

enough. I would not make the same mistake this time. I super-glued nine

big lead fishing sinkers into the fuselage - three in the nose and six

behind the rear cockpit bulkhead. This proved to be adequate.

With the cockpit, nose gear and lead weights installed,

the fuselage halves were brought together.

Wings and Tailplanes

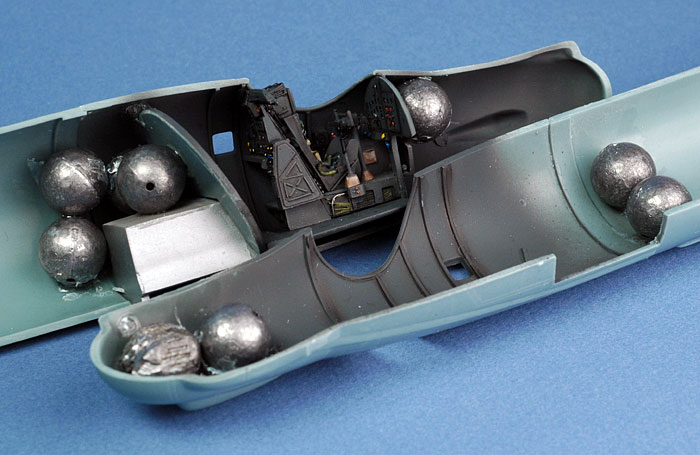

Once the excess resin was removed from the top of the

resin gear bays, they fitted inside the thick Canberra wings without

further preparation.

Trailing edges looked a little thick so I scraped the

insides and gave them a sanding before assembling the wings. The big

wing halves mated up quite well considering the absence of locating

aids. I had a little overhang (top wing over bottom wing "overbite") on

one wing, but it was easily sanded to shape. I sanded the trailing edges

again after assembly to improve the appearance of this area.

I glued the bottom intake half to each wing, then glued

the top half in place. In retrospect, I realised I would have been better

off gluing the top half to the top wing first. Some trimming and

shimming was required to get the intakes to fit properly, but this extra

effort meant that very little filler was needed once the parts

were glued in place.

Classic Airframes supplies two plastic wing spar rods to secure the big wings to

the fuselage. The holes for the spars in both the wings and the fuselage

were partially flashed over, so I reamed them out with a sharp hobby

knife.

The top of the wing joining surface was sanded to remove a slight ridge.

This added a valuable extra degree or so of dihedral.

I replaced the plastic spars with brass tube. The spars were

passed through the fuselage and

attached to the wings to either end using super glue, effectively tacking

them in place. Tamiya Extra Thin Liquid Cement was then flowed into the

upper and lower seams at the wing root. The fit was once again very

good, with almost no gaps and absolutely no steps on the upper surface,

and only narrow gaps at the lower joins.

At this stage, the angled horizontal tail surfaces were assembled. Holes

were drilled for brass rod spars, and these were also secured to the

fuselage using super glue. Tamiya Liquid Cement finished the job once

the correct dihedral was set.

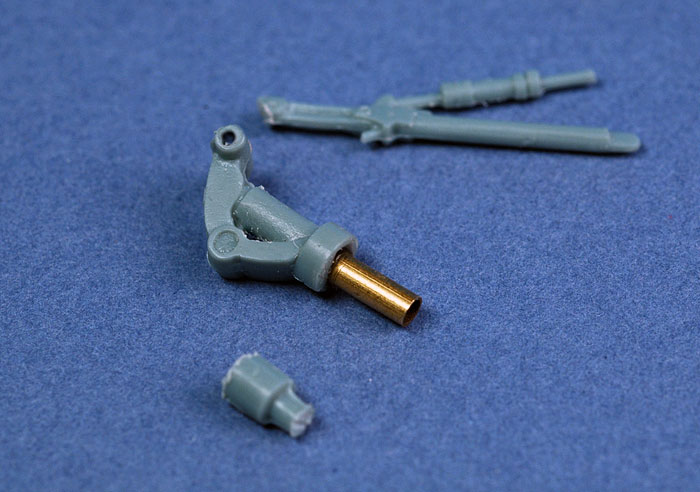

While the glue on the main airframe set, I modified the

nose gear strut. Without modification, the nose gear sits too high,

giving the front of the Canberra a slightly stalky appearance. I cut off the

top of the gear leg above the oleo collar (about 3/8" of leg plus

the locating pin), and sliced off the retraction strut. The top of the

remaining nose gear was drilled out and a short length of brass tube was

inserted as a replacement locating pin.

I also cut off the locating pins for the wheels and

drilled out holes for replacement brass pins.

The fit of the new resin fuselage tail cone proved to be

slightly tricky. First, I managed to glue the part on crooked. I cut the

rear of the resin part off and re-glued it at the correct angle. There

was also a fairly large gap between the top of the resin part and the

bottom of the fin. This was filled with Milliput, and sanded to shape

when the two-part epoxy putty had cured.

A few places on the airframe required putty, including

the upper fuselage seam and the front of the nose; a step on one side of

each engine intake; and the engine tail cones. Before painting, the wing

tip tanks were assembled and installed, and the canopy was masked and

glued to the fuselage. All the remaining dangly bits would be installed

at the last moment.

Before painting, I drilled out locating holes for the

various antennae and masts. I also drilled out three holes around each

jet intake to depict the starter cartidge vents. The holes were filled

with Krystal Kleer, resulting in a recessed circle - a close enough

representation for my purposes. The sundry resin scoops and vents on the

lower fuselage were installed at this stage too.

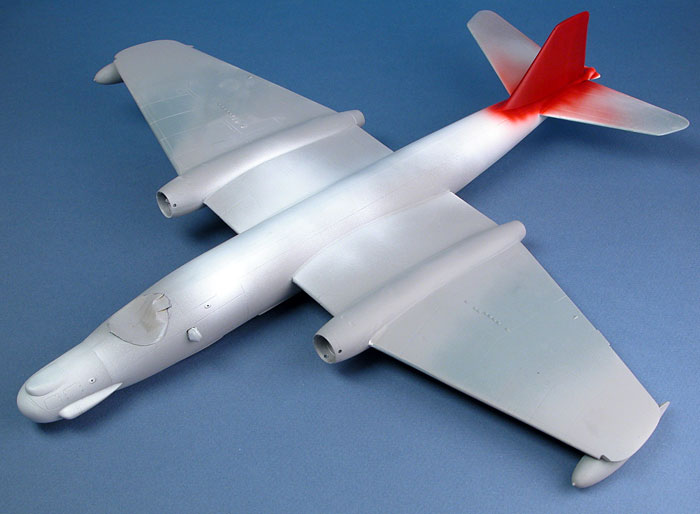

The assembled model was sprayed with an overall coat of

Tamiya Grey Primer straight from the can. This highlighted a few lumpy

areas that needed a bit more attention with the sanding stick.

Next, these repaired areas and the entire tail were

covered with Tamiya's Fine White Primer, also from the spray can. Red is

notoriously difficult to spray, and I wanted a nice even coat of white

underneath to ensure even coverage.

Despite this careful preparation, the red acrylic paint on the

tail cracked and crazed. There was no alternative but to sand the tail

back to its white undercoat. Once this messy task was complete I

repainted the tail, this time using lacquer spray paint (Tamiya TS-49

Bright Red) decanted into the paint cup of my Aztek airbrush. This

delivered a high gloss, even finish. The only problem was that it was

not the same shade of red as the Squadron flashes on the kit decals. Ah

well, can't have everything...

Click the

thumbnails below to view larger images:

|

|

|

|

|

The red paint crazed, so the tail was sanded back to the white primer |

|

|

|

|

With the repairs made and the top colour sprayed, the airframe was masked for the lower surface colour. |

|

|

|

More woes - I damaged the camouf;age paint in front of the fin, requiring more repairs. |

|

|

The lower surface now received a coat of Tamiya AS-2 Light Grey IJN.

This seemed to be a reasonable match for RAF Light Aircraft Grey. The

fast, smooth finish straight from Tamiya cans is a real Godsend on the

these big models.

The camouflage demarcation lines on the lower fuselage and engine

nacelles were masked with Tamiya tape, then Gunze acrylic H336 Hemp was

applied as the upper surface camouflage. Gunze paints are usually quite

glossy when dry, but this colour was dead flat.

The two rectangles above the navigator's position were masked and

sprayed black to represent windows. The larger rectangle slightly aft -

a dielectric antenna panel - was painted Tamiya XF-55 Deck Tan. At this

time I also painted the bases of the aerial masts black and re-masked

the canopy to spray the white line of sealing tape.

The entire airframe now received a coat of Future floor polish to

provide a glossy surface for decals. During spraying, a thick glob of

Future ran down

the rear fuselage. I stupidly wiped the area with a cloth dampened in

Windex, and promptly stripped the paint in the area. More running

repairs...

Classic Airframes' decals performed beautifully over the

glossy surface of the model.

The yellow wing walkway lines were time consuming to cut

to shape and position on the model, but I love the way they break up the

broad surfaces of the wings.

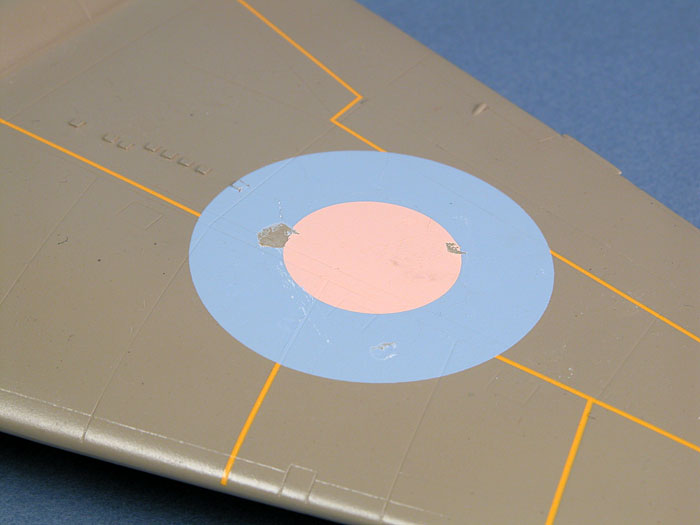

Once all the decals were down, I applied Micro Sol. To

my horror, the upper wing decals crazed quite noticeably when the Micro

Sol had dried. I brushed a coat of Solvaset over the top to see if this

would settle the crazing, but it had no effect. In desperation, I

finally brushed Mr Mark Softer (no, it is not a typo, that really is

the product's name) onto the two decals. This stuff is really aggressive

and, as I should have guessed, it actually melted a few spots into the

decals.

I had little choice other than to sand the decals back

as far as possible without damaging the surrounding camouflage, and

re-paint the markings.

As it turned out this was not entirely a bad thing as

the pink in the kit decals is a bit insipid. I mixed up a brighter batch

of pink using Tamiya acrylic Red and White. This was sprayed onto the

centre of the upper wing roundels. While I was at it, for the sake of

consistency, I resprayed the pink on the fuselage roundels and fin flash

too.

Click the

thumbnails below to view larger images:

|

|

|

|

First, a custom mix of RAF Roundel Pink was sprayed onto the centre of the roundels. |

|

|

|

The pink section of the fuselage roundels were also resprayed. |

|

|

|

|

Masks were cut from Post-It Notes using an Olfa Circle Cutter. |

|

|

|

Extreme decal repair - the new blue and pink roundels. |

|

|

Weathering

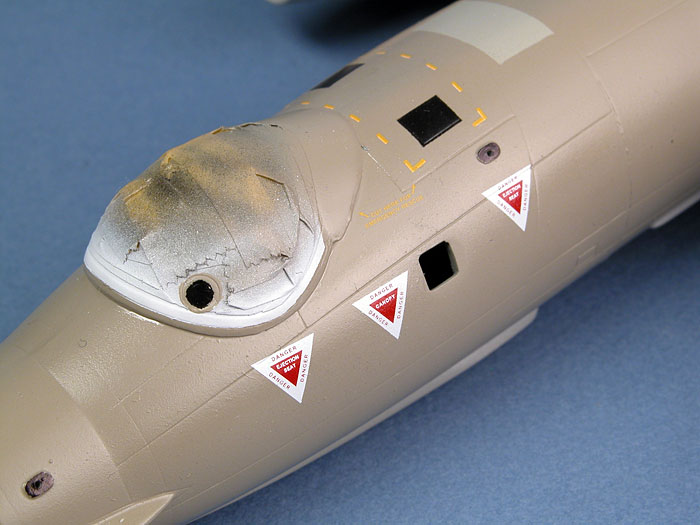

While searching for reference on the Internet, I was

fortunate to find a

great photo of this specific aircraft, serial WD955, on airliners.net.

The photograph showed a peculiar pattern of heavy

weathering on the fuselage aft of the cockpit and on the lower fuselage.

My best guess is that smoke from the inboard starter cartridges created

the heavy staining (maybe mixed with dirt and condensation on the

surface), while the bottom of the wing and the open inner gear doors

generated a mild venturi effect, funneling the filth along the lower

fuselage. There is also an obvious stain running along the engine

nacelle from the starter cartridge vent.

I filled the airbrush paint cup with a very thin mix of

Tamiya Flat Black and Red Brown, carefully building up fine lines of

this dirty mix to duplicate the pattern of weathering in the reference

photo. I also added some heavy weathering on the bottom of the fuselage

and underneath the wings, especially between the engine nacelles. More

streaking was added below the tail surfaces and, ever so lightly, on

selected panels around the nose. The same mix was used to create some

random streaks and spots on the wings and fuselage. Panel lines on the

nose and the engine nacelles, plus control surface hinge lines, were

subtly emphasized with a thin wash of Tamiya Semi-Gloss Black acrylic

applied with a fine brush.

I wanted to avoid geometrically dividing the wing by

highlighting panel lines. I felt that this would be unrealistic, and

would also distract from the distinctive yellow wing walks. Even

so, I needed to do something to break up that vast expanse of

Hemp. I decided to try something different. After spraying a couple of

coats of Polly Scale Flat over the completed paint job, I applied a

mottle of Gunze Hemp over the top. This mottle was fractionally paler

than the varnished paint of the same colour, and also had a very

slightly different gloss level. I was pretty satisfied with the result.

The final step of weathering was to add a few tiny

"chips" around the fasteners on various nose panels using a silver

artist's pencil.

Click the

thumbnails below to view larger images:

|

|

|

|

The distinctive weathering pattern is first sprayed onto the forward fuselage and engine nacelles. |

|

|

|

The addition of some subtle panel highlighting and a flat coat makes a big difference to the effect. |

|

|

|

Weathering is now almost complete. |

|

|

|

|

The undercarriage was assembled and secured to the model

at this time. I was pleased to find that the shortened nose gear

leg greatly improved the sit of the model. Now it hunches down

authentically over its nose gear.

Various antenna masts and aerials were painted and glued

in place. I installed a few extra devices that I found in reference

photos, although they were not mentioned in the instructions. These

included two fine "T" aerials underneath the fuselage fabricated from

fine copper wire; and two blade antennas - one under the forward nose

and one on top of the rear fuselage. These were sourced from spare

antennas included in the Classic Airframes kit. The reference photo of

WD955 also seemed to show a pitot tube on the side of the forward

fuselage. I robbed a pitot from an old Hobbycraft Bf 109 kit for this

job.

Finally, the photo suggested that this aircraft was

fitted with "disco lights" - rotating orange beacons above and below the

rear fuselage. I chucked a short length of Cutting Edge clear orange rod

in my Dremel Motor Tool and shaped the top into a dome using

progressively finer grades of sanding sticks. When I was satisfied with

the basic shape, I cut the light off to an appropriate height and dipped

the part in Future for a brilliant shine. This process was repeated for

the second light.

Click the

thumbnails below to view larger images:

The final job was rigging the antenna wire from my

pre-drilled hole at the top of the fin to the two aerial posts on the

port side of the forward fuselage. E-Z Line was used for this job. The

more I use this elastic rigging, the more I like it!

Classic Airframes' brand new 1/48

scale Canberra T.17 was a lot of fun to build.

Detail is impressive, construction is

challenging in places but was never frustrating, and this late version

certainly presents a different facade compared to the earlier B.2 and

TT.18 kits. When confronted with a photo of my

model, a friend of mine declared that the aircraft looked like a "wart

nosed witch". I actually think it looks pretty attractive, but

even if you don't agree, you can't say it is not interesting!

This is the fifth Classic

Airframes kit I have built so far this year, and the second Canberra. I

will be grabbing a third Canberra to build some time in the future too

(I want to have one in silver with the white upper fuselage).

If you don't mind a bit of parts

preparation and can anticipate problems before you commit to glue, you

should have few problems building any of Classic Airframes' 1/48 scale

Canberra family.

Thanks to Classic Airframes for the

sample.

Click the thumbnails below to view larger images:

Model,

Images & Text Copyright © 2006 by

Brett Green

Page Created 24 September, 2006

Last Updated

21 February, 2007

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search