|

Classic

Airframes new 1/48 scale

Boulton Paul Defiant

by

Phil Hale

|

|

|

Bolton Paul Defiant Mk.I |

Classic

Airframes' 1/48 scale Defiant Mk.I and II kits

are both available online from Squadron

For a detailed examination of the kit

contents, see

Steven "Modeldad" Eisenman's in-box review here on HyperScale.

I am back with another pair of beauties from Classic Airframes. Since

Modeldad has given a good review of the kit break down, I wonít waste

your time going over the ground again.

I will say that the surface of the plastic is very smooth and glossy

and this makes for a good base for painting. The clear parts are very

clear and can be polished to a high shine.

I like to have the clear parts as shiny as possible because this

makes a good contrast with the flat finish.

Now on to the build!

The fuselage is broken down into five major parts. The nose parts are

separate pieces to allow the modeler the option to either a Mk I or Mk

II. The chin scoop and the radiator are bigger on the Mk II. The Mk II

nose has the chin scoop molded as part of the nose where as the Mk I

scoop is a separate piece. The fit of both of these nose parts to the

rear fuselage is excellent requiring little to no filler. It is broken

on a natural panel line and if a little care is taken you will not have

to sand much at all. I had to sand a little on the right side but not

enough to lose any detail. I usually join the front and rear sections

before I glue the halves together. This kit was no exception. I would

rather fill the seam on the top or bottom instead of the side.

I painted the cockpit painted and got it ready to install. Clean up

of the cockpit took a little while has the pour stubs are large under

the cockpit area. Make sure that you cut or grind the stub completely as

this may present problems when attaching the wings to the fuselage.

There are large stubs on the wheel wells and must be completely cut

off. The top part of the wheel well will be thin but there is plenty of

room and will not harm the beautiful detail in the well.

I put the fuselage halves together and sanded them down before I

installed the cockpit and rear floors.

The fairing behind the turret is a separate piece and could be

positioned in the retracted position. This part fits well. You can slip

the cockpit in place from the underside through the wing opening. The

turret floor and the turret fairing floor can be put in after the

fuselage is together. The cockpit is a good tight fit and you can jockey

it in place then glue from the underside.

You need to install the wheel wells before gluing the wings together.

Youíll know very quickly if you have not taken enough of the pour stubs

off when you fit the upper wing surfaces to the one piece bottom

surface. If the wing parts fit well then you probably wonít have any

problems when mating the wings to the fuselage. When I mated the wings

to the fuselage, I found the underside surfaces fit very well, almost

perfect. I had to sand a little under the nose to wing area and none at

the rear portion. I did have a gap at the forward edge of the upper wing

to fuselage joint. There is a stiffener that runs the length of the

upper wing to fuselage joint. I sanded this area smooth. After sanding

was completed, I replaced this stiffener with vinyl tape. You get this

tape in large sheets at a shop that makes outdoor signs. It comes in

many colors and can be lightly sanded. I use it to replace lost panels.

It takes paint very well and can be masked over.

The rear stabilizers are butt joints but I used liquid cement and

allowed them to dry for several hours. Even a butt joint with liquid

cement makes a good strong bond. The rudder is a separate piece and

needs some attention. There are some depressions on both sides that will

require filling and sanding.

I had no trouble fitting the Mk I scoop on the nose. I did have a

little trouble with the radiators on both. There are raised areas on the

underside of the wing to mark the spot to attach the radiator. This is

fine for the Mk I but the Mk II radiator is longer and wider and does

not fit these marks. I used a little five minute epoxy to fair this in.

You just put the epoxy in the joint and wait a 30 seconds and then wipe

it off with a damp cotton swab (Q-tip). If you let it dry too long, you

can still wipe it off with a swab dipped in denatured alcohol. You might

try sanding these marks off and then attaching the radiator. I did not

as I did not want to lose any of the detail in this area.

The

turret is in two pieces and care must be taken in gluing it together. I

used a piece of the vinyl tape to conceal the seam. The

turret is in two pieces and care must be taken in gluing it together. I

used a piece of the vinyl tape to conceal the seam.

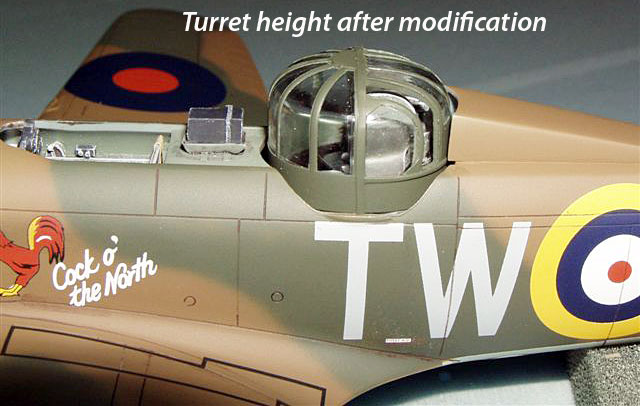

The turret parts fit very well but it sits a little high on the

fuselage. Since the turret is the focal point of this kit this may seem

to be a serious problem. Fear not, there is an easy fix. The interior of

the turret causes it to sit too high. I trimmed the sides of the resin

interior and I was able to slide the turret in place. I have include

photos to show where I trimmed.

Is this deadly accurate? I donít know because I have very little info

on this kit. I do know that it looks like a Defiant when completed.

Click the thumbnails below to view larger images:

I do wish that the canopy was open to show the beautiful cockpit

detail but Iím sure that someone will release a nice vacuum formed

replacement.

Painting and decaling presented no problems. You might want to check

your references as some Defiant Mk Iís had Duck Egg Green undersides

instead of Sky. According to Richard Caruana from SAMI, my Mk I had sky

undersides.

The decals are MicroScale and are very well done.

I had one problem of my own making that delayed this review. I use

Scotch Transparent tape to make the clear covers over the wing lights.

Normally, this causes no problems but this time I had little pieces of

trash that got inside the covers and I could not get them out. I had to

redo the covers on both models and this caused a several hour delay.

Overall this is an excellent kit and I would recommend it to a

modeler that has never built a limited run kit. It fits well and this is

plenty of detail.

I believe that this kit is one of the best limited run kits on the

market. Purists will find fault but NO kit is perfect. Granted there are

some that are close but one thing to remember. The guys that produce

these limited run kits usually donít have the benefit of multi-million

dollar computer equipment. Plans can be off because of paper shrinkage.

The masters are hand made and may not be deadly accurate. They may be a

little too short or long and this shape may be slightly off but they are

kits. I mean, we donít have to carve them out of pine ourselves. People

that want to nit-pick these kits need to offer their services to MPM,

Sword, Azur, and the like. Iím sure that they would appreciate and

welcome the help.

Thanks to

Classic Airframes for the samples

Click the thumbnails below to view larger images:

Model, Images and Text Copyright © 2004

by Phil Hale

Page Created 10 November, 2004

Last Updated

10 November, 2004

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search