|

Hasegawa's 1/48 scale F-15J

Year Of The Dragon

Part Two

by Aleksandar Šekularac

|

|

|

F-15J |

HyperScale is proudly sponsored by Squadron.com

Continued

from Part One

I was sitting in my new hobby room

trying to think what was I doing last. Opened couple of boxes that

looked promising, found few kits in various stages of construction… One

Blenheim Mk I in 1/48 scale looked particularly promising. I took it out

and played with subassemblies for a while. After a week I’ve put it back

in its box. It wasn’t it. Few more weeks passed.

After more half-hearted tries like this, I finally decided to focus,

finish my F-15, and not allow attention to meander until I do. This is

what worked for me in the past, and it didn’t fail me this time.

Carry On

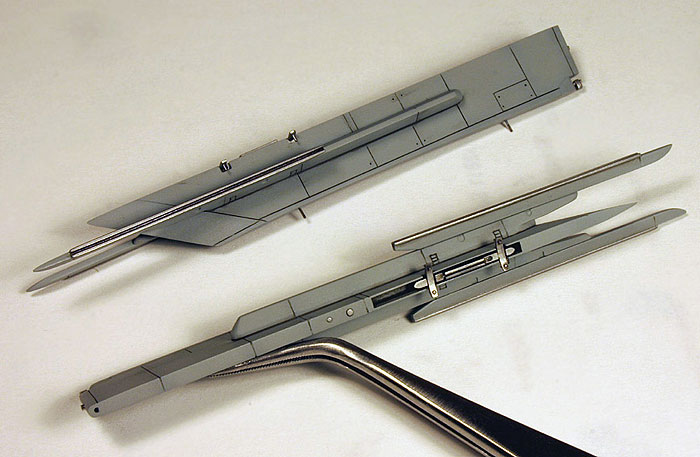

Much rework went into the two main

pylons under the wings. These are rudimentary in the kit, and no detail

is present at the main attachments, whereas on the real aircraft this is

a fairly busy place. I resorted to scratch building again. Cutting out

the block of plastic from the bottom of the pylon, where the whole

locking mechanism lies, and replacing this with thin plastic walls, left

the hollow box inside. Then I fashioned the separate mounting column,

with sway bars and detailed it to my taste. This was in the end inserted

in the pylon box, after painting and weathering.

Click

the thumbnails below to view larger images:

Some detail was added to the rear end

of the pylons as well. Metal locks that attach pylon to the wing

structure were scratch-built from pieces of plastic and metal wire, and

another small cylindrical outlet was added by drilling a hole and

inserting a short piece of syringe tubing, standing a bit proud of the

surface. Since I wanted clean model, without any under-wing payload and

only the central fuel tank attached, I detailed the sidewinder rails, as

they will be left exposed. I started by deleting the plastic tongue for

attaching the rocket, and then making a recess for the rail, by slowly

pushing the straight saw alongside the middle of the face. I finished it

off with some sand paper.

Big central fuel tank received

scratch-built sway bars at the attachment point, some rivet dental and

also a new rear pylon lock. When painted, assembled and weathered all

the effort shows up.

Canopy

This turned out to be a real test of

willpower. After sanding smooth the longitudinal seam of the clear

parts, I polishing them with Tamiya Polishing Compound, and added a coat

of Future. I like to apply it with a hand brush, rather then immersing

the whole part in a pool of Future. I find that the thin layer applied

with a brush dries more evenly. After canopy dried, all the small bits

where attached to the underside of the front frame and along the sides.

Using slow setting epoxy glue is a

good choice for attaching canopy, since one can remove any excess glue

with damp Q-tip, hours after application.

After 24 hours the bond was cured and I proceeded with work, only to

discover a lot of sanding dust that came from somewhere, and was now

stuck to the inner side of my crystal clear closed canopy. Watch the

temper, steady now! I had to carefully break off the canopy, without

actually cracking the transparent parts and try to minimize damage to

inside details. While I managed to save the canopy, there were now many

small pieces rattling inside the nose section. Pilot also decided to

eject in this emergency. By shaking the fuselage section under different

angles I managed to get all the pieces out. Clean, sand, polish,

repaint, re-glue…

After another 24 hours, for the epoxy to cure, I couldn’t believe when I

again discovered more dust under the canopy, plus some nice fingerprints

that I left with the second gluing! Much swearing in several tongues

followed.

I had to break open the canopy AGAIN. Clean, sand, polish, repaint…This

time around I wasn’t taking any chances, so I used my vacuum-cleaner to

suck out any remaining dirt from the cockpit cavity and the nose

section. Additionally, I washed everything in water. After repairing it

all, I carefully re-glued the canopy, this time wearing cotton gloves.

Another 24 hours passed and the work was finally finished. No dust, no

fingerprints, third time is indeed a charm…

With this build I tried several new

products and techniques, which in effect changed to a great degree the

way I finish a model. This was all done in an effort to improve control

and finesse in those critical steps when the subject takes its final

shape.

Things I Like & Things I Don’t

After reading some accolades about

Mr.Surfacer I decided to try it out myself and see if this primer really

makes a difference. Not so long ago I didn’t quite understand importance

of priming the model, and would most often skip this step altogether,

and immediately load the airbrush with the finishing paint. But, the

layer of primer gives 3 important benefits that I now fully appreciate:

-

Identifies all the imperfections

that still exist on the surface (giving one a chance to fix them)

-

Improves a lot adherence of any

subsequent layer of paint,

-

Allows for much thinner and finer

layers to be applied over it, as it provides opacity.

Mr.Surfacer is a Gunze Sangyo product,

and it comes in different grades. I have grade 500 (coarse) and 1000

(finer). The coarse grade sprays somewhat rough, but it dries quickly

and can be sanded to perfection. It can be also used very effectively as

liquid putty. The finer grade sprays smoother, and can be also further

improved by fine sanding and polishing.

In short, I became a believer.

Together with Tamiya masking tape this is probably the best hobby

product I ever tried.

Painting

This was also the first model I

finished with my new Iwata Hi-Line airbrush. I must admit that it felt

like flying first class long distance after being used to “economy”. Old

Aztek airbrush served me well for last 5 years, but it started showing

me lately why plastic is meant for models, not for tools. A small “H”

link inside its double-action mechanism failed repeatedly, usually in

the middle of some big project. Then I had to send it back to Testor and

wait for the replacement body. While I find Aztek’s exchangeable nozzle

system to be really practical, the materials used for the mechanism are

simply not robust enough. Whenever the paint finds its way through the

piston sleeve, and inside the airbrush body, which is just a matter of

time, it will cause extra friction, and next time you try to pull back

the trigger this “H” link will brake. Testor does not recommend opening

airbrush body, as it’s supposed to be sealed (“snap-tight”), but it

isn’t really, and to prevent failure one has to clean the insides. The

whole hassle was finally too much for me, so I bought this chromed

marvel from Japan, and all I can say is: it’s worth the money…

Click

the thumbnails below to view larger images:

Lastly, I also changed the washing

technique for this model. My standard way would have been to use enamel,

or lacquer based finish, and then water-based pastes for washes. This is

a very safe method, as the painted layer is completely indifferent to

soapy water used for cleaning of the wash. However, I didn’t like

capillary characteristics of the water-based pastes, and also when they

dry it is sometimes hard to remove stains they leave behind.

This time I used a “standard” wash made of artist-oils diluted in

turpentine. Oils can be mixed very well, they flow excellently, they dry

slowly, and they can be cleaned with almost no additional turpentine,

using only cotton tuffs (a lot of them). The only requirement is that

the undersurface must be acrylic. For a gloss coat I used Future (acryl

based), and this worked very well. I plan to use this method from now

on.

Decals

Decals were the starting point for

this project, and their application proved to be a deciding moment, and

major undertaking as well. Main motif, the huge white dragon spanning

the wings, is provided as three-piece decal. I have never before worked

with decal this big and so complex, and I hope I won’t have to do it

again. It is very difficult! I started by cutting out all three pieces

of the dragon and trimmed them closely. Then I was able to plan the

approach by “dry-fitting” it to the wing.

Despite reading earlier an opinion on the web that this dragon decal is

too large, I would suggest that the decal is correctly sized (at least

for Hasegawa kit), but fitting has to be done very carefully! When I

compare the model with images of the real aircraft from the web, dragon

motif looks identical in size and position.

I started with the tail of the dragon.

This decal includes starboard wing Hinomaru, which gives you one locator

point. The other locator was the tip of the forked tail that has to fit

as close as possible to the rear left corner of the starboard wing flap.

As soon as I had this piece in a more-or-less correct position I moved

on to the torso of the dragon, and after that to the head-piece. These

huge decals dry slowly, and by adding droplets of water one can apply

all three of them and have them still sliding on the surface. This is

essential for fine adjusting. Although the decals are very well

produced, their shear size makes them prone to tearing. Curvature of the

wing-fuselage joint and the engine bumps further complicate this

process. My decals tore in several places, but as long as they don’t

suffer some major damage they can be repaired.

Dragon was the first decal I applied to the model. I started one Friday

evening, and I was still working on it on Sunday (I did sleep in the

meantime if someone wonders), reapplying the softening solution, looking

for air bubbles and correcting all the tricky corners. There were

visible lines of different opacity where the two pieces joined together,

and some other places where decal was torn. These spots had to be

carefully and very lightly sanded, and then airbrushed, to blend

everything together. I also did some spot-repairs of the dragon’s

blue-gray border with a fine hand brush.

When this work was done I felt I crossed the Rubicon. There were still

uncountable number of small markings to be applied, but this just

required time, with no major obstacles.

In hindsight, much more elegant solution to this subject would be to

have masks for airbrushing white surface of the dragon, with only the

gray border and red eye provided as decals. This being said, I must give

praise to Two Bobs for a job well done. Subject selection, research, and

decal quality is excellent. Even the smallest stencils are authentic,

and shown in the right place.

This was a trailblazing journey for me

in more ways than one. The motivation came completely from a stunning

looks of this subject, and its availability in scale. To quote a line

from one film I like: “It is a funny feeling being under the wing of a

dragon. It’s warmer than you think”. Now I may decide to stay with the

theme, and build a Bae Hawk T1 with the red dragon from Wales in some

near future...

Photography

All the photography you see here is

done with my favorite Canon Digital Rebel SLR and following lenses:

-

Canon EFS 18-55 Zoom

-

Tamron f2.8, 90mm Macro

Click on the thumbnails

below to view larger images:

LaGG & Lavochkin Aces of

World War 2

Aircraft of the Aces 56 |

|

|

|

|

Author: George Mellinger

Illustrator: Jim Laurier

US Price: $19.95

UK Price: Ł12.99

Publisher:

Osprey Publishing

Publish Date:

November 21, 2003

Details: 96 pages; ISBN: 1841766097 |

|

|

Model, Images and Text Copyright © 2006

by Aleksandar Šekularac

Page Created 02 February, 2006

Last Updated

04 February, 2006

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search