|

Tamiya's 1/48 scale

F4U-1A Corsair

Part One - Construction

by Tony Bell

|

|

|

Chance-Vought F4U-1A Corsair |

Tamiya's

1/48 scale F4U-1A Corsair is available online from

Squadron

Tamiya first released their 1:48 F4U-1 Birdcage Corsair almost ten

years ago back in 1997, followed in the next couple of years by the -1D

and -1A kits. Typical of Tamiya kits, they are well engineered with good

(albeit a bit heavy in some folks’ opinion…) surface detail. The cockpit

is nicely detailed straight from the box, as is the engine.

The kit

provides dropped flaps and the option of posing the wings either folded

or flat. There are some minor issues with the kit, including the much-ballyhoo’d

boarding step in the right inner flap (which the kit instructions

indicate should be filled in - the horror!), and the slightly off

looking braces on the canopy sliding hood.

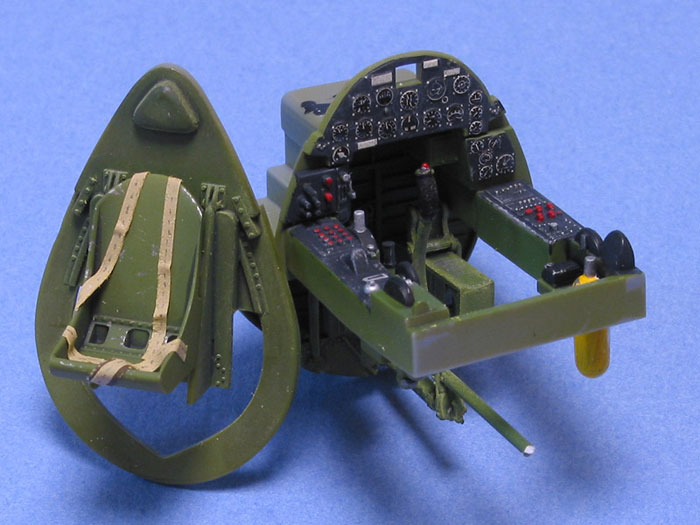

The Cockpit

Okay. everybody, say it with me:

“Construction-started-with-the-cockpit.”

And so it did with this model. As this was to be an out-of-the-box

build, I didn’t do anything extra to the cockpit, aside from thinning

the back and sides of the seat. The seat back is particularly thick, but

my 8” Bastard file made short work of it. I briefly toyed with the idea

of adding a map case to the right console and replacing the trim wheels

with disks of sheet styrene, but in the end I decided I would keep the

canopy closed and stay true to OOB.

I started off by airbrushing Tamiya semi-gloss black in the nooks &

crannies of the interior, being careful to keep it in the areas of

natural shadow. I did this on all the cockpit bits, the fuselage side

walls, wheel wells and landing gear doors - anything that was to be

painted Interior Green. I thinned the black about 80% with rubbing

alcohol and sprayed it at about 10-15 psi. I then mixed up a batch of

Interior Green from Tamiya paints and airbrushed the interior bits,

misting it on in light coats to allow the pre-shading to peek through.

I applied a mix of India ink and Future floor polish (although any

acrylic clear gloss will do) to all the I.G. areas in order to add depth

to the recesses, followed by an airbrushed coat of Polly Scale clear

flat. I brush painted the cockpit side consoles “scale” flat black (i.e.

dark grey) and then dry brushed everything with a medium green-grey

mixed from Payne’s Grey, Chrome Yellow and Titanium White artists’ oil

paints. Various switches and knobs were picked out in red, silver, white

and gloss black with a fine brush and Citadel paints. A silver

Prismacolor pencil was used to draw some scuff marks and chipping.

The seat harness was made from strips of masking tape painted Tamiya

Buff, with the stitching was drawn on with a needle sharp pencil. The seat harness was made from strips of masking tape painted Tamiya

Buff, with the stitching was drawn on with a needle sharp pencil.

For

the instrument panel I simply trimmed the carrier film from the kit

decal and applied it with liberal amounts of Solvaset setting solution.

Once it was dry, I sprayed it with Polly Scale Flat and applied a small

dab of five minute epoxy to each gauge face for the glass.

The Engine

The engine is also very nicely detailed, in spite of the simple, three

part construction. The cylinders were brush painted with Citadel

“Gunbolt Metal”. The funny thing about this paint is that if you add

rubbing alcohol directly to in an attempt to thin it, it will turn into

a curdled, gooey mess. If on the other hand you dip the paint brush in

alcohol and then dip the brush in the paint and mix it up on a palette,

you end up with a very brush-friendly mixture that goes on smoothly and

dries quickly. Go figure. Chemistry was never my strong suit. I also

brush painted the rocker covers with Citadel “Chainmail Silver” and the

pushrods with “Chaos Black”. The black pushrods were subsequently

brushed with Future to make them glossy.

The reduction gear housing was airbrushed with Gunze Mr. Surfacer 1000

(a nice mid-grey) while the bolt heads were brush painted silver. The

whole engine was then treated to a wash consisting of Poly Scale clear

satin mixed with India ink.

Assembly

This was one of those models that put up a bit of a fight, in spite of

it being a Tamiya kit. The fuselage halves went together without a fuss,

and the cockpit didn’t even require any glue. I left the bottom seam

unglued so that I could spread it a fraction of a millimetre and achieve

a perfect fit with the middle lower wing piece.

Tamiya has engineered the fuselage halves in a modular fashion to make

them common with the Birdcage variant, with an insert just behind the

cockpit to differentiate between the versions. The insert seams fall on

panel lines, so careful attention to fitting and gluing is needed to

ensure that they are consistent with the moulded panel lines. The

instructions would have you glue the fuselage halves together first,

followed by the insert. I decided that, in the event of a less than

perfect fit, it would be easier to deal with one seam at the top of the

fuselage rather than two seams on the sides. I therefore assembled each

fuselage half separately, applying liquid cement from the inside. As it

turns out there was a slight gap on top which was easily filled with a

small amount of superglue.

The circular fuel tank panel just ahead of the cockpit had to be

rescribed after I sanded the fuselage seams, and the inner and outer

ring of fasteners surrounding the panel were tediously restored with a

micro drill bit chucked in a pin vise. I rescribed a couple of small

panels on the top of the fuselage using a scribing template and a sharp

sewing needle. One neat little trick I’ve learned when rescribing panels

is to brush a small amount of lacquer thinner in the newly scribed line,

let it dry and then sand with 1000 grit wet sandpaper. This avoids

pushing the plastic back into the groove and results in a very clean

line. I used a fine razor saw to restore the panel lines that crossed

the fuselage seam, and, while I was at it I used the saw to cut the

panel lines of the control surfaces and trim tabs perpendicular to the

trailing edges.

The wings were a bit of a pain in the butt (now I know why most Tamiya

Corsairs are seen with the wings folded). Not counting the flaps, the

wings are broken down into six main parts (upper right, lower right,

upper left, lower left, upper inside right, upper inside left and bottom

centre) and eight secondary parts. It was a challenge to get it all

lined up and level with the wings down, in spite of the Tamiya fit and

engineering of the parts.

My normal habit is to attach the wings to the fuselage and then use them

as the reference to align the horizontal stabs. With this kit it’s

better to do it the other way around, as the horizontal stabs have very

positive interlocking alignment tabs that make it impossible to screw

up. As it turned out I had to gently steam the right wing root and crank

it up a degree or two in order to line things up. To do this I filled a

saucepan with an inch of water and sealed the top with a piece of

kitchen foil. I brought it to a boil on the stove and poked a hole in

the foil with a pencil, producing a narrow jet of steam. I gently warmed

the plastic at the wing root while applying pressure and then quenched

the plastic under cold running water. I repeated this a few times until

the wings and stabs lined up.

The fit of the leading edge intake pieces was so-so, requiring some

filling (I used superglue) and rescribing to fair them in. I filled the

slight gap between the wing root and the fuselage with Mr. Surfacer 500

and wiped the excess away with a Q-Tip soaked in rubbing alcohol after

it had dried for about 20 minutes.

Although I usually dip my canopies in Future, the kit’s transparencies

were so clear and free of distortion that this time it was unnecessary.

I masked the canopy panel by panel with Tamiya tape by applying a piece

of tape and burnishing it down with a toothpick, making sure to work it

into the edges of the frames. Then, with brand new No. 11 X-acto blade,

I slowly and carefully trimmed the tape while holding it up to the

light, applying just enough pressure to cut through the tape. The braces

on the sliding hood look funny to my eye, curving inward and upward at

the front. Fortunately Tamiya provides two sliding hoods, with and

without the braces. I used the one without and simply masked it with the

braces in the correct position.

I attached the canopy with liquid cement applied sparingly with a fine

brush and filled the seam with Mr. Surfacer 500. By applying the

Surfacer with a fine brush and carefully sanding it with fine wet ‘n

dry, I was able to avoid damaging the canopy and the engraved panel line

detail.

Continued in Part Two

Model, Images and Text

Copyright © 2006 by

Tony Bell

Page Created 14 July, 2006

Last Updated

17 July, 2006

Back to

HyperScale Main Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search