|

This is part

three of my marathon three part posting on my

U-2S "Senior Span/Spur" project.

After over three

and a half years on my work bench, I can finally

call this one DONE.

In parts one and

two of my U-2 project build posting, I discussed

a brief history of the U-2 and the building of

my U-2S model. In this part I will discuss the

painting and finishing of the model.

Follow these

links to get to the other parts of this posting.

| |

Part One: |

Aircraft History, Model

Kit Description, and

Fuselage Interior Construction |

|

| |

Part Two: |

Fuselage Exterior,

Wings, and

Completed Airframe Construction |

Model Surface

Details and Scribing

|

There is really only one painting option for

making a late model U-2S -- black, black, and

more black. With this one camouflage option

available, the question became, "How do I make

an all-black aircraft interesting?". I decided

that I needed airframe details to help fill in

the long areas of flat nothing. To that end, I

postponed painting for just a little while

longer and scoured over all the U-2 references I

had looking for panel lines and access panels on

the airframe. I figured that some extra scribing

would go a long way to adding interest into the

surface of the model.

Even before I started painting, I was

starting to really like the way the model was

looking with all the added access panels and

details.

Some further scrutiny of the Senior Spear

antenna farm on the belly of the aircraft and

the provided blade antennae from both Cutting

Edge's update set and Italeri's

Senior Span kit made me decide to handle the

blade antennae a little differently than I had

originally thought. I already had drilled holes

in the locations I thought I wanted the blade

antennae to be, but a late discovery of a

bottom-side image of a U-2S in the landing

pattern changed my opinions of the locations I

chose to drill the holes. So, I filled the holes

and relocated the antennae as outlined below.

| |

Corrected Blade Antennae

|

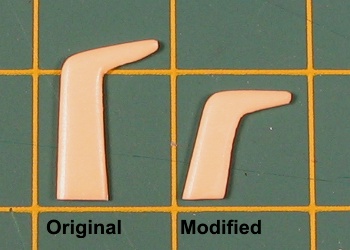

Also, I knew that both the Cutting Edge

and Italeri blade antennae were too big.

I had not taken time to determine just how much

they were too big. After some careful

measurements from the pictures I had, I did the

math to find that both the Cutting Edge

and Italeri blade antennae were

substantially too big. Both were incorrect in

the angle that the "hockey stick" antennae were

mounted. I liked the shape of the Cutting

Edge blades better, so I started with theirs

and trimmed them down to more appropriate sizes.

See the image to the right for a comparison of

the original and modified antennae.

The first thing

you will note in the picture is the height of

the blade antennae. I cut off about 0.1" inches

(measured at the leading edge) from the base of

the antennae. I also changed the angle of the

base so that the "blade" of the "hockey stick"

would be more parallel to the airstream. The

shortening of the blade in addition to the

change in angles substantially reduced the

overall height of the blades, solving the

problem of having them hit the ground on the

complete model. Additionally, I slightly reduced

the width of the blade and the length of the

tip.

Using my newly modified "hockey sticks" as a

basis, I then cut down the other blade antennae

to correspond to the size change in the "hockey

sticks".

Since I was cutting the blades from their

mounting plates in order to fix their size, I

decided to make my own mounting places (thinner)

out of 0.010" strip styrene and attach the

mounting plates to the aircraft before painting.

The images below show one of the reference

images along with a picture of my model (before

painting). The model image shows the final

positions of the blade antennae (really just the

mounting plates) as best as I could interpret

from the reference images. Note these are only

marginally different from the positions given in

the Cutting Edge instructions.

Antennae Positions --

Reference Image |

Antennae Positions --

Model |

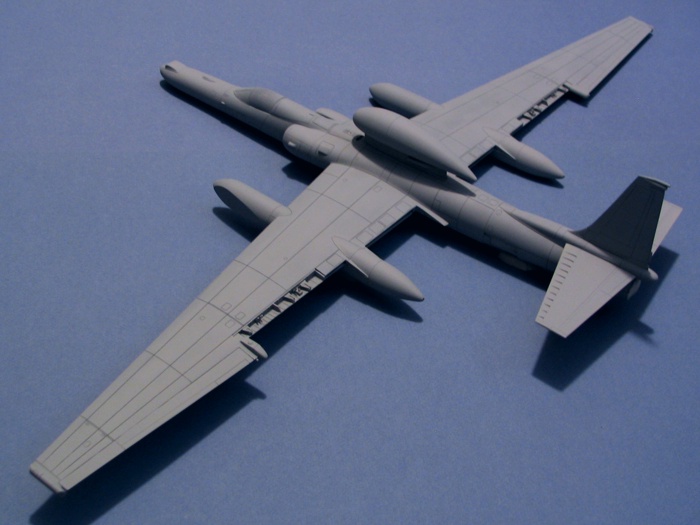

After adding all the three-dimensional

details that I could find, it was now time to

start painting. I wanted to verify all my work

was clean, so I did something very out of

character for me and primed the model. I used

Model Master D.Ghost Gray and painted the

whole model. Had I known the trouble this would

cause me later, I would have decided not to

prime the model.

Primed Model |

After having a

mostly black plastic model (with some gray resin

portions) on my desk for the last couple years,

it seemed strange to see this all gray model.

One thing was very evident -- the primer showed

that my scribe lines were way deeper and more

pronounced than I would have liked, but it was

well past the time to fix that, so I moved on.

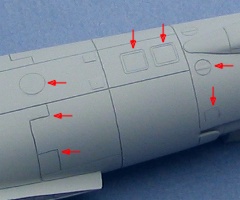

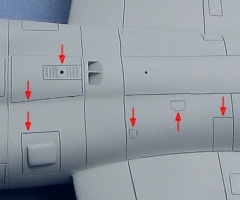

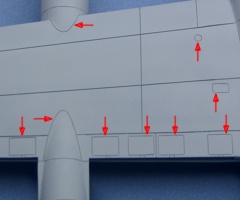

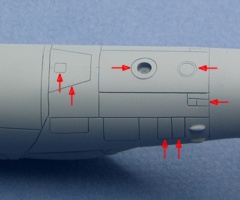

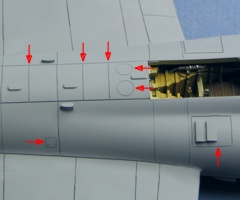

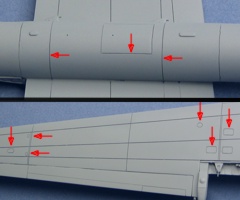

The following images show some of the additional

scribing I added to the model. The red arrows in

the images highlight the additional lines.

Upper Rear Fuselage |

Rear Fuselage Sides |

Upper Mid-Fuselage |

Lower Forward Fuselage |

Flap Actuator Access

Panels |

Fuel Cell and Wing Tip

Access |

Pictures from

the World Airpower Journal issue that covers the

later U-2 had plenty of shots of U-2 aircraft

showing a wide variety of weathering patterns. I

decided to try to capture a weathered look

without making the aircraft look too busy.

The first thing I had to do is start thinking

in terms of very dark gray, not black. This

would then give me the latitude to vary the

shades and simulate a paint scheme similar to

what I was seeing in pictures. I started by

painting the whole model in Model Master

Interior Black. Previous usage of this color by

me over bare plastic showed it to be a nice

extra dark gray color. Over the gray primer

paint, however, the color turned to a near black

color. This was much darker than what I was

initially intending as the overall color of the

model.

Now I had to decide what to do. The problem

was that I liked the dark color I got when

applying this paint over the gray primer. I

decided to keep it, which changed some of my

other plans for painting on the model. I masked

off and painted the ASARS II nose in a very thin

true black. Most all pictures of ASARS equipped

aircraft from the 1990s show the nose being

darker than the rest of the aircraft. I kept the

paint thin and just misted it on until I had

slightly darkened the nose. I did the same

darkening to the noses of the super pods, the

forward portion of the Senior Span pod, and the

engine intake lips.

Most aircraft in pictures show a faded

pattern across the upper wings and fuselage with

very slight darkening near panel lines. I mixed

up some Engine Gray (F.S.36076) and misted it in

a wide spray pattern across the inboard wings

and the upper fuselage. Before doing this paint

fading, I masked off the fairings for the super

pods. Images showed these were generally darker

than the surrounding wing areas, probably

because they are removable and thus not as

weathered.

A couple images showed aircraft where the

outer wing fuel cells had been recently

maintained. This resulted in a dark gray outline

to the panels. I masked the wings and applied

this outline using Engine Gray (F.S.36076).

While painting full-strength Engine Gray, I also

masked and painted the panels under the nose, in

front of the ECM blisters on the engine intakes,

and the front and rear faces of the ECM pods on

the wing tips. Most images show these areas

being a lighter color than the rest of the

airframe.

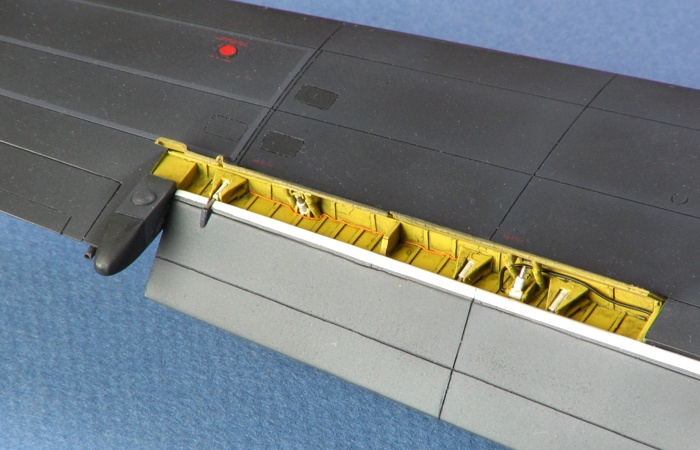

The "scuff zones" on the upper wing flaps and

the small pie slice at the front of the vertical

tail are white. I had painted these in gloss

white and masked them before starting the

overall colors. The spoiler wells are Chromate

Yellow with the actuator pistons painted white.

I have no detail color references for the wells,

so I chose to make the pistons white just to

liven up the area.

Ready for Gloss

Coating |

With all the

major area painting done, I was really starting

to like the looks of the model. Next, I held my

breath and applied a gloss coat using Floquil

Crystal Coat to the whole model. This gloss coat

changed the colors of the model considerably.

All the things that should have been darker but

did not seem to be much darker suddenly were

darker. I felt vindicated over the color choices

I had made and that the color variations were

not too over-done (a BIG fear I had before the

gloss coat). Then, it was time to start applying

decals.

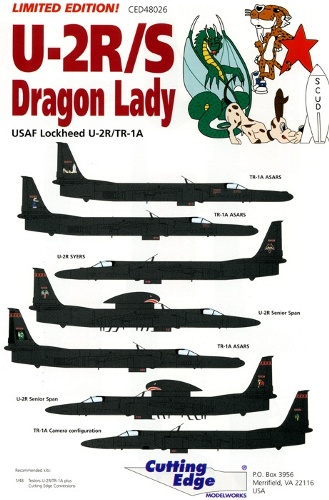

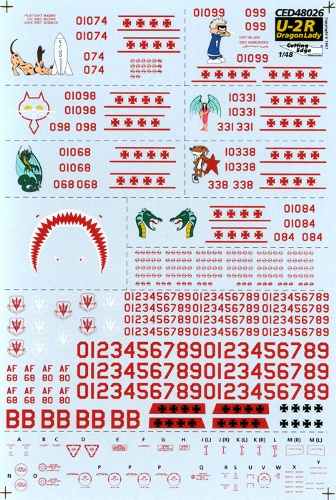

The decals for the unit markings came from

the Cutting Edge TR-1A / U-2R/S "Dragon

Lady" sheet CED48026 (seen below). While there

are several nice tail art aircraft on this

sheet, they all go on aircraft from the 1991

Desert Storm conflict. I was limited on using

any of these because of the airframe details I

already had applied to the model. Specifically,

the GPS dome fairing on the left wing was not

present for the 1991 Desert Storm period.

Besides, what I really wanted to build was an

aircraft that used the "BB" tail code like the

one I saw at the Andrews AFB air show. So, I

ignored the neat tail arts and just used the

generic "BB" tail codes and numbers from the

bottom portion of the sheet.

Decal Cover Page |

Decal Sheet |

The Cutting

Edge sheet I originally purchased years ago

turned out to have a severe registry problem.

All the "BB" and serial number decals had the

white backing showing from the sides of the

markings, making them look like they were

shadowed. A quick trip (well, not SO

quick being a six hour round trip) to Meteor

allowed me to pick up a replacement. My

off-register sheet must have been a fluke, as

the first two sheets I picked off the pile were

in perfect register. The sheet includes a bit of

airframe data markings. Loving data markings, I

could not help but to add these to the model,

too. Most U-2 aircraft seem to maintain their

data markings pretty well, so these are not out

of place.

Studying the pictures of the aircraft I saw

at the Andrews AFB air show, I saw many airframe

panels had silver/gray fasteners lining the

panels. I decided it would make this all black

aircraft look more interesting to incorporate

these fastener patterns into the model. I got

the idea for this from Gekko Graphics

silver scratches weathering decals. I measured

the panels that were to get the fastener decals

and drew up the art work on my PC. After

cross-checking and verifying the patterns and

sizes, I printed them on my ALPS printer using a

silver foil ribbon. Covered with gloss and flat

coatings, these dulled down nicely to a metallic

gray color.

The following is the art work I used for my

custom decals (reduced in size to save space). I

also changed the background color in this image

to make the fastener patterns easier to see.

Custom Decal Art Work |

When the decals

had dried, I applied another gloss coat to seal

them. Then, I applied a satin finish to the

entire model using Floquil Flat Finish. I

have never gotten a flat finish from Floquil

Flat Finish, instead always giving me a nice

satin finish. Lastly, I applied a flat coat to

specific parts of the model using Polly Scale

Flat Finish. After this flat coat, the red of

the tail markings seemed extremely bright on the

dark airframe. I toned down the red color by

doing a light misting of black over the tail.

The effect better captured the look of the

markings I saw on real aircraft in pictures.

Decaled and Satin/Flat

Coated |

For weathering,

I did very little beyond what I had already done

with the colors of the paints I used. Most of

the weathering was built into the already

applied color coatings. Also, the scribed lines

were deep enough to be seen without needing any

washes applied to them. I did do some minor dry

brushing to pop out and enhance a few surface

surface details (like the stiffening ribs on the

tails).

For the record, this black finish on the

model was more troublesome than other color

finishes I have applied. The biggest issue was

that I could not make touch-ups without having

them show. It was almost as bad as a natual

metal finish in this respect. What I fould is

that the colors painted from the bottles

(brushed or air brushed) were very different

from the same bottled colors that had been

gloss, satin, and/or flat finished. I have some

areas on the bottom that really got me annoyed

around the blade antennae because my touch-ups

are not matching the surounding paint. Oh

well...

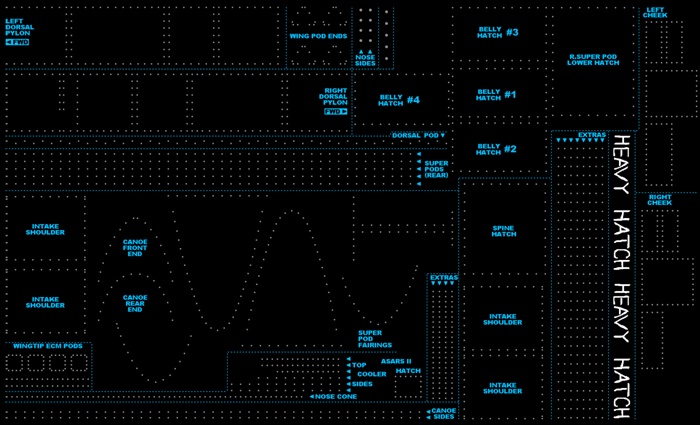

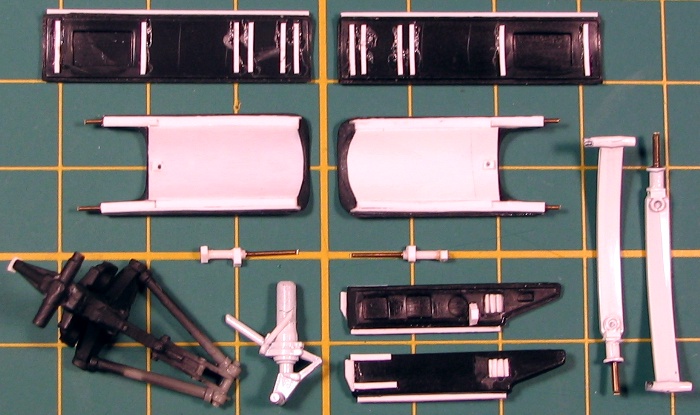

With the model painted and decaled, it was

time to work on the landing gear. With all the

detail I had added to the rest of the model, I

did not want to come up short on the landing

gear, so I started doing some scratch building

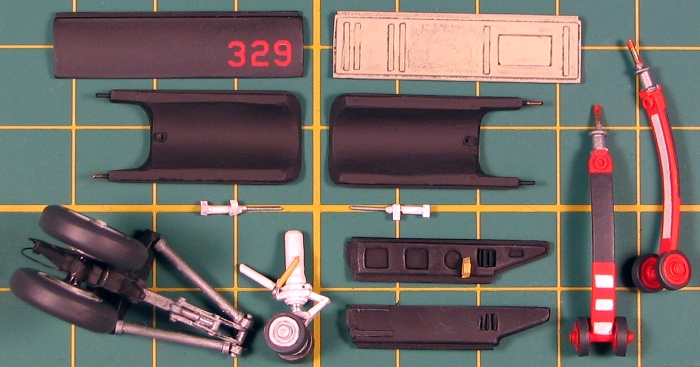

and detailing. The following image shows the

landing gear items that I updated.

Updated Landing Gear

Items (Mostly Unpainted) |

What I did to

the landing gear items is as follows:

- Main Wheel Well Doors: The kit

pieces are not bad. They only lacked some

inside ribbing. I added the ribbing with

0.010"x0.020" styrene strips. I also added

0.020" square strips on the mounting edges

of the doors to provide a lip to assist in

aligning the parts when I attached them to

the model.

- Main Landing Gear: Pictured is

the Cutting Edge landing gear strut

that I made the master for with the

kit-provided landing lights attached to it.

On looking closer at the strut, I found I

needed to add some small wiring harness

details. Not easily visible in the images,

after completing the painting of the strut,

I added some black hydraulic lines and

wiring to the back side of the strut and two

MV Lenses for the landing lights.

- Tail Wheel Well Doors: Out of the

box, these could work, but I have images

that showed details that the kit had missed.

I cut holes in the doors and added vent

louvers in the rear sections. I added a

scoop to the leading edge. I also added the

retraction linkage connect point on the

inside. Like on the main wheel well doors, I

also added 0.020" square strips on the

mounting edges of the doors to provide a lip

to assist in aligning the parts when I

attached them to the model.

- Tail Landing Gear: The kit piece

for the strut is quite close to the real

thing. All I did was add the linkage lines

for the steering collar and drill holes to

receive the linkage arms for the wheel well

doors.

- Wing Pogo Struts: The pictured

items are already painted white. I cut down

and re-built the mounting shanks, replacing

the kit's plastic mounting pins with brass

wire. This would help the pogos survive

years of display on my model shelves. I also

added the tie-down lugs to the front and

back of each pogo.

- Speed Brakes: Like the main wheel

well doors, the speed brakes are not bad

right out of the box, but I was not happy

with the thinness in the kit pieces. There

were also a series of knock-out pin flaws on

the inside surfaces. I decided to re-build

the inner side of the speed brakes. This

made the brakes more bulky as well as

covered the knock-out pin flaws.

- Speed Brake Actuators: The kit

piece for these were too small. Besides,

having rebuilt and deepened the speed brake

wells, I needed longer actuators than what

the kit provided. The only course was to

scratch build new actuators from styrene rod

and brass wire.

After all the updates were done, I painted

the pieces and attached them to the model. The

one landing gear item I did not change from the

kit was the rather complicated looking

retraction linkage for the main wheel well

doors. Testors/Italeri seemed to do quite

well on this piece, so I just removed the mold

marks, paint it, and installed it as is.

Updated Landing Gear

Items (Painted) |

Now that the

model was sitting on its landing gear, I could

start adding all the blade antennae. Having

already attached the mounting plates of the

antennae and pre-drilled all the antennae

locations before painting, the antennae were

fairly easy to attach. I drilled a hole in the

bottom of each antenna with a #80 drill bit and

glued in a piece of fine brass wire. The wire

acted as a locator pin and made a positive

attachment to the aircraft in each place I had

drilled a hole on the bottom of the model.

Underside Antenna Farm

While attaching the blade antennae, I painted

some of the antennae bases in the light

yellow/green that I used in the wheel wells.

Then, a quick swipe with a paint brush colored

the actual blade antennae. The Cutting Edge

instructions state that the antennae vary in

color. I found most pictures showed black

antennae, so I chose to make most of them black.

For variety, I did pick off a couple odd

antennae in medium gray. Pictures also showed

the antennae were glossy finished. After the

colored paint dried, I gave each blade a swipe

of clear gloss paint.

Attaching the wing flaps and spoilers came

next. No matter how long I had played with the

detail fit of the flaps, I always found I could

tweak something else to improve the fit even

more. Finally, I gave up and added glue.

The spoiler wells were detailed with some

fine wire. I have no pictures of this area on

the real aircraft, so I just added the wire to

make things look busy. The wire is

ignition wire for 1/24th

and 1/12th

scale car models.

Left Wing Spoiler Well

As is almost always the case for me,

detailing around the cockpit and the interior of

the canopy were the last things I did on the

model. I scratch-built the defogging pipe in the

rear section from copper wire. I added the

latching handles on the right frame edge with

fine brass wire. Finally, I added the rearview

mirrors and movable sunshade with its guiderail

to the front edge using fine brass wire and

sheet styrene. Cutting Edge provides a

nicer version of the personal fan for the left

side of the canopy than the kit-provided

version, so I used the Cutting Edge

version. Italeri's instructions tell you

to mount the fan to the canopy glass, but it

really is attached to the canopy frame. I

removed the molded locator lines from the glass

and attached the fan to the canopy framing.

Research showed that the majority of the

canopy is clear plexiglass with only a couple

inches of frame running around the outer edge.

What looks like a solid upper portion is really

a self-adhesive sunshade applied from the inside

of the canopy glass on the upper rear section.

The kit molds this detail correctly with the

line for the shade only present on the inside of

the canopy. I masked the inner canopy and

painted the sunshade from the inside.

One item to add on the upper left windscreen

frame was the rearview mirror. The kit-provided

piece for this was way too bulky, so I

scratch-built a new mirror from a piece of

styrene rod, some 0.005" brass wire and some

0.005" sheet styrene. This looked much better

and was more dainty, like the one on the real

aircraft.

With all this work done around the cockpit

and canopy, I attached the canopy in the open

position and completed the project.

Cockpit and Canopy

So what

EXACTLY have I built?

|

This picture was the prime inspiration for

the project.

68-10329 Reference Image

This biggest difference between the above image

and my model is the ASARS II nose. While I have

other images showing that 68-10329 can carry the

ASARS II nose, the above image shows it at a

time when the ASARS II nose was not being

carried. This aircraft (and more specifically my

model) bristles with antennae all over its

surfaces. What are they all and what do they do?

From studying various books, I have learned the

following.

- The nose is the ASARS II

synthetic aperture radar. This side-looking

radar is used to make detailed radar maps of

target areas from considerable stand-off

distances. Sample images in books show

astounding clarity in the images, and I am

sure that the images declassified for

publication are only a fraction of the true

capability of the system.

- The antenna farms on the lower airframe

and the canoe fairing on the left super pod

are all part of the Senior Spear

COMINT system which gathers and classifies

various forms of communication signals. The

flattened portions of the forward sections

on the super pods are for Senior Ruby.

This is an ELINT system that gathers

information on radar emissions. The

combination of Senior Spear with Senior Ruby

together on one aircraft is also referred to

as Senior Glass.

- The four "hockey stick" blade antennae

mounted on the top and bottom of each of the

Senior Ruby super pod noses are unknown to

me. The image above of aircraft 68-10329 is

the only image I have showing these, and

since I wanted as many antennae on the model

as I could, I added them. Perhaps they were

an experimental extension of the Senior

Spear fit.

- The dorsal antenna pod is a satellite

up-link antenna to allow real-time

interpretation of the information gathered

by the U-2. It is referred to as either

Senior Span or Senior Spur.

Senior Span is for transmission of SIGINT

data recorded through the Senior Glass

systems. Because I also attached the ASARS

II nose on the model, this aircraft could

have a Senior Spur installation which

transmits radar imagery recorded by the

ASARS II system. Differences in the

transmission process dictate that the dorsal

pod is either Senior Span or Senior Spur. It

can not be both. The external details of the

pod appear to remain the same, no matter

whether Senior Span or Senior Spur are

inside.

These are my best guesses based on what I

have read. Considering the classified nature of

the U-2, these interpretations could be correct

or just elaborate fabrications. I do know that

some of the references I checked contradict each

other on various points. Whatever the case, all

the assorted antennae, bumps, and bulges give

the model a very determined look that lives up

to the U-2 pilot's motto -- In God we

trust, all others we monitor.

Did I mention that the finished model is

HUGE?!?! The completed model has a 26 inch

wingspan. I need to find a creative way to fit

this model onto my display shelves in the living

room. The following image shows just how big the

final model is as I proudly hold it up for the

camera.

Dave Aungst Holding the

Completed Model

I believe all the update sets I used on this

model are still available from Cutting Edge.

If you get the current Italeri "Senior

Span" release, you really will not need the

Cutting Edge Senior Span/Spur/Spear set. The

ASARS II nose fit problems are not impossible to

overcome, but they will require time to work

out.

This model is a record-breaker for me.

- It holds the record for the highest

number of hours I have invested into any

single model -- 180.8 hours. And,

this time tally does not include a

further 86.2 hours I spent building

the masters for some of the U-2 update sets

I incorporated into the model. Just the

"extra detailing" time alone -- 82.3

hours -- is double the time a "normal"

project build would take me.

- The work I did constructing the master

for the main wheel bay constitutes the

largest pure scratch-building effort I have

yet to undertake. Scratch-building the tail

wheel well / engine exhaust and wing flaps /

spoilers just added to the tally.

- It has the largest amount of resin

updates that I have ever put into any one

model. I used a total of seven different

resin update sets on the model that replaced

over half the kit parts and about 25% of the

overall volume the original model with

updated, enhanced, or otherwise changed

pieces. Interestingly, there are no etched

metal pieces anywhere on the model.

I really enjoyed building this model,

although I am really, REALLY, REALLY

tired of black finishes for a little while. And,

in the process of researching for the project, I

learned that there is much more to the U-2 than

what meets the eye.

(Newest to Oldest)

-

U-2R/S

Walk Around by David W Aungst

On-Line HyperScale Reference, 2003

-

U-2: The

Second Generation by Chris Pocock

World Airpower Journal, Volume 28, AirTime

Publishing, 1997

-

Dragon

Lady by Ted Carlson / Toyokazu Matsuzaki

Koku-Fan Magazine, Volume 1996-04, Bunrin-Do

Company, Limited, 1996

-

Recce Tech

by Paul F Crickmore

Osprey Color Series, Osprey Aerospace

Publishing, 1989

-

U-2

Spyplane in Action by Larry Davis

Squadron In Action #86, Squadron Publishing,

1988/2002

-

Lockheed

U-2R/TR-1 by Jay Miller

AeroFax MiniGraph #28, AeroFax, Inc.,

1988

-

Lockheed

U-2 by Jay Miller

AeroFax AeroGraph #3, AeroFax, Inc., 1983

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search