|

Focke-Wulf Fw 190D-9

Superdetailing the Big Tail

Dora

by

Doowan Lee

|

|

|

Focke-Wulf Fw 190D-9 |

Part One

building the wings, fuselage

and engine

Tamiya's

1/48 scale Focke-Wulf Fw 190D-9 is available online from

Squadron

This is Tamiya's 1/48

scale Focke-Wulf Fw 190D-9 detailed with several update sets and many scratch-built

parts.

Click the thumbnails below to view larger

images:

Wings and Tail

Since the Fw 190D-9 is a very popular WW II airplane, I was looking for

something that had not been done.

Having reviewed as many internet model

articles on the airplane as possible, I realized that few Fw 190D-9s had

both a superdetailed Ta-152 tail and wheel well. The wheel well could be

precisely correctly with the MDC update set. However, superdetailing the

big tail was a bit more complicated task than I expected since I couldn’t

just use aftermarket resin tails. An easier solution would’ve been

kit-bashing an Italeri Ta-152H kit. However, I didn’t feel like wasting

money and a perfectly fine kit. As a result, I ended up using a regular

tail and heavily modify it with putty and my trusty dremel tool. The tail

wheel service panel was easy to simulate since I had all the necessary

parts from the FM detail Fw 190D-9 update set.

Modifying the outside was a completely different

story. In retrospect, I would’ve saved a lot of time and trouble by simply

kit-bashing the Italeri Ta-152H.

Click the thumbnails below to view larger

images:

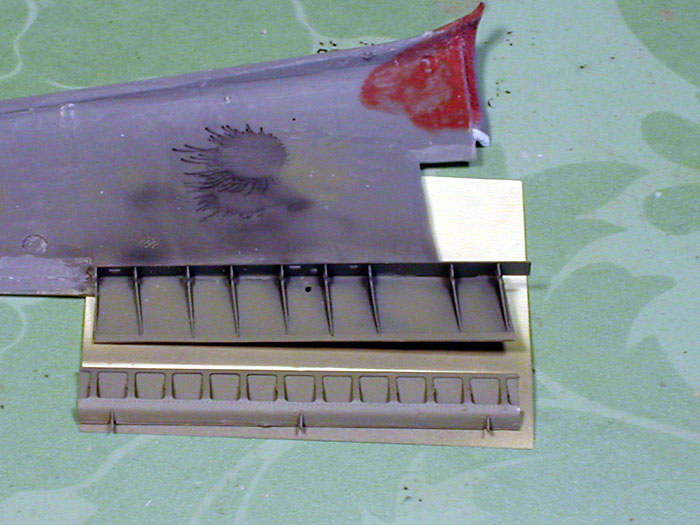

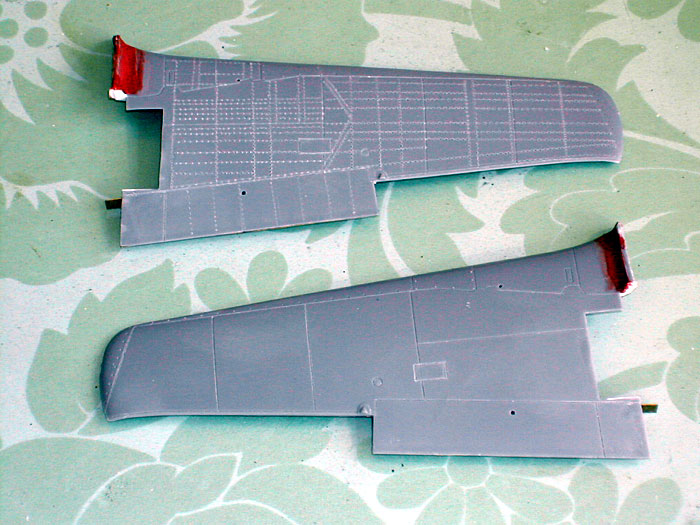

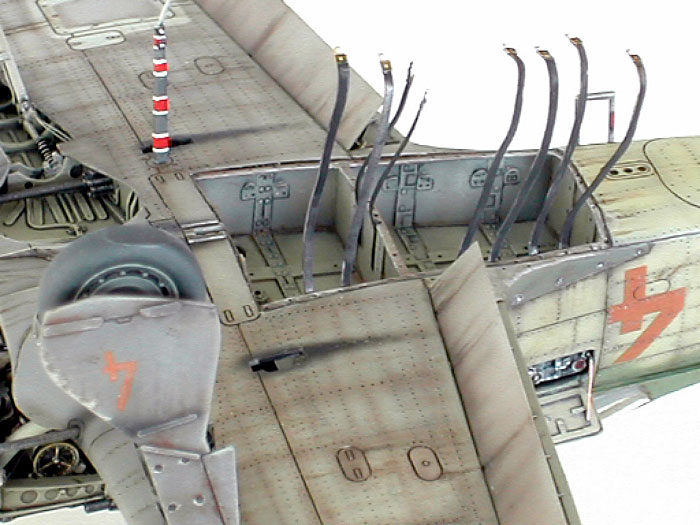

For the wings, I had to correct several panel lines which were omitted in

Tamiya’s 190D-9. I used Parts and Accessories’ flaps and Cutting Edge’s

control surfaces. Fitting the flaps was pretty tricky and required many

hours with my dremel tool. The flaps themselves required a lot of careful

bending and assembly, but the details were excellent.

Click the thumbnails below to view larger

images:

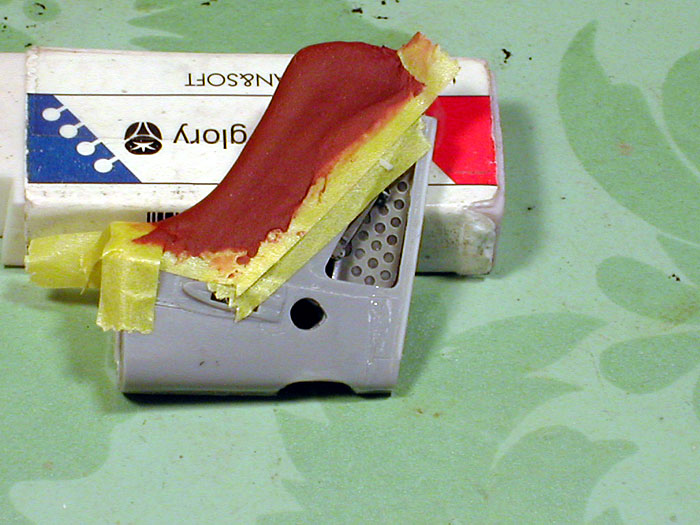

Next was simulating rivet

marks.

I have studied all my

reference photos on the aircraft and realized that the surface was not

very smooth at all.

Although I tried to justify not doing this tedious time-consuming

detailing, all the reference photos of the 190D-9 showed fairly visible

rivet marks even from a distance. In fact, in almost all close photos, I

could see distinct and worn-out rivet marks throughout the aircraft. Rivet

marks were especially visible around the cockpit and accessible panels and

hatches.

This observation led me to simulate rivet marks on the entire model.

Relying heavily on “Aero Detail: Fw 190D,” I used a sharp scribing pin to

individually simulate the rivets. Although it was very time consuming to

say the least, I think this is the best way to do the job. I tried

different types of metal gear wheels and other tools, but they did not

give me the exact round shape or density of the rivet marks. I used

masking tape to guide each panel lines.

It took a few days plus a couple of blisters on my thumb. Well, there was

no deadline, thus I went on with the task. I paid extra attention to keep

the rivet marks subtle. This is done by sanding the entire aircraft with

2000 grit sandpaper until the rivet marks were subtle enough to be seen in

close proximity but fade away from a distance. In retrospect, I am happy

with what I did to simulate rivets all over the plane. However, I don’t

think this will be something I would do on a regular basis for my future

projects.

Click the thumbnails below to view larger

images:

Fuselage and Engine

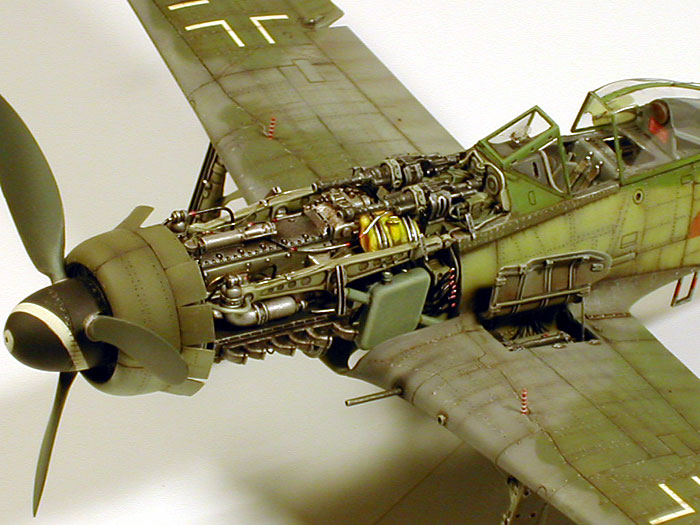

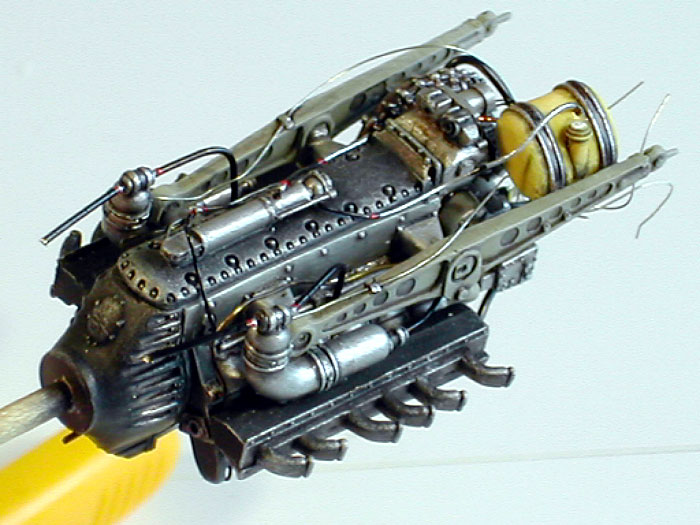

As for the engine,

I compared several aftermarket sets. Aires’ engine looked great and

dynamic but a little oversized. Verlinden’s engine was nice, but

undersized and a bit simplified. After measuring and comparing with all

the reference books I have, I concluded FM Detail’s interpretation of the

Juno engine was the most accurate. The support rails attached to the

engine were scratch-built as well. I relied on Brett Green’s Fw 190D-9

close-up article at

http://www.clubhyper.com/reference/fw190d9enginereferencebg_1.htm for

wiring and extra detailing.

Click the thumbnails below to view larger

images:

I am particularly pleased with the cowling support rails I built from

scratch. Also, the supporting arms of the engines seem too thin compared

to reference pictures. I used aluminum tubes instead. I think they have to

pretty thick and sturdy to support the weight of the engine. Other than

that, the FM details’ engine and detail parts are just fantastic, well

worth the price.

The radiator cowl ring received some extra detailing too. I added small

tube-shaped openings at 6 and 12 o’clock. Also drilled out a small hole at

the bottom panel line. Lastly, I also added rivet marks around the cowl

ring. I might have overdone the rivet marks, the painting made them subtle

enough. (cowlingparts02.jpg, radiator-cowling-prewashed01.jpg,

brown4_51.jpg, brown4_79.jpg around here) I used MDC’s beautiful spinner

and propellers instead of the parts that came with the kit.

Click the thumbnails below to view larger

images:

The radio comes from Aires’ Luftwaffe radio set. All the small hatches

were scratch-built. The center auxiliary fuel tank is also scratch-built.

I could’ve used the Verlinden update part, but I didn’t like the detail

and look of it. I also added fastening clips to the harness of the tank. I

then scratch-built the starter crank and placed it next to the auxiliary

tank. A lot of frames and wires were added to make sure the fuel tank had

the right background looks. Once they were painted and washed, I added the

enervator control cables. A couple of small fuel ‘caps’ were opened and

scratch-built.

Click the thumbnails below to view larger

images:

I found a nice drawing of the fuel tank compartment in the Mechanics of Bf

109 and Fw 190. I’ve always found simulating the mechanical looks of

airplanes challenging and satisfying. Naturally, I decided to open the

compartment and show the fuel tank harness. First, the compartment panels

were removed from the lower wing. I used my Dremel tool to thin the

surrounding areas to get the right scale thickness. Frankly, it was a very

tedious process that I intend not to repeat in the foreseeable future…

Then it was just cutting the right plastic panels, drilling holes, and

putting them together. Once painted and weathered, it was inserted into

the fuselage.

Fitting the compartment to the frame was particularly challenging for a

couple of reasons. First, the floor of the cockpit was a bit too thick

which made the compartment protrude too much. Time to summon my trusty

dremel… Second, both fuselages had to be thinned substantially since I

failed to calculate for the thickness of the kit parts. This is where I

should’ve compromised accuracy a little for a better fit. Once again, time

to summon my trusty dremel.. There was also an unforeseen problem as well.

Now that the fuselage parts had been thinned to the extent for them to

look translucent, I punctured through them several times while I was

embossing rivet marks around the cockpit. Time to summon putty and sand

paper… Of course, the wing didn’t fit well with the compartment despite my

‘sincerest’

efforts to calculate everything in 1/10 millimeter. Time to summon my

trusty dremel, putty and sand paper.

The result is very satisfying, but

only in retrospect.

Click the thumbnails below to view larger

images:

End of Part One

Go to Part

Two - landing gear, cockpit, painting, markings and weathering

Go to Part Three - Gallery of

Additional Images

Focke-Wulf 190

Modelling Manuals 20 |

|

|

|

|

US Price: $17.95

UK Price: £12.99

Publisher:

Osprey Publishing

Publish Date: May 25, 2002

Details: 64 pages; ISBN: 1841762687

|

|

|

Model, Images and Text

Copyright © 2004 by

Doowan Lee

Page Created 23 February, 2004

Last Updated

17 March, 2004

Back to

HyperScale Main Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search